Common Causes of Metal Roof Leaks

Leave a CommentMetal roof leaks are not unusual, but they can be extremely costly. Undetected and unchecked, a leak can allow moisture to collect on roof supports, interior walls and ceilings, and even structural supports that keep the building standing. Over time, moisture can cause these building components to rust or rot. Standing water in the building interior can also promote microbial growth, which can cause severe air quality issues and health problems.

At APM Hexseal, we understand that an impenetrable metal roof is critical for keeping your building protected from moisture. Our sealing products are specifically designed to withstand the extreme conditions and corrosion that are common in outdoor roofing applications. In this article, we discuss common causes of metal roof leaks, how to fix them, and ways to prevent future leaks.

At APM Hexseal, we understand that an impenetrable metal roof is critical for keeping your building protected from moisture. Our sealing products are specifically designed to withstand the extreme conditions and corrosion that are common in outdoor roofing applications. In this article, we discuss common causes of metal roof leaks, how to fix them, and ways to prevent future leaks.

Common Problems of Metal Roof Leaks

The most common cause of metal roof leaks is the roofing screws used to attach the panels to the frame of the building. The screw design, installation method, and angle can all affect the way that the roof performs over time. Metal roofing screws create a hole in the roof, but generally do not seal the opening. Even when a sealant is used, screws that are under-driven, over-driven, or installed at the wrong angle all present opportunities for moisture to leak under the metal paneling.

In addition to poor screw design and installation, other causes of metal roof leaks include:

- Faulty Screws: Poorly performing screws with misaligned threads or breakage can create an opening in metal roofing. Over time, rubber washers degrade and lose their sealing properties.

- Missing Sealants: Quality metal roofing installations include sealing hardware or liquid sealants that prevent leakage from screw holes, panel seams, and other vulnerable points. These sealants must be replaced over time due to environmental wear.

- Overlapping Seams: If your metal roofing is not installed flush, the overlapping seams can create a space for liquid to pool and leak into the interior of the building.

- Stack and Curb Flashings: Flashings are plastic sheets just under the exterior roof and walls of a building or the rubber boots that surround extruding pipes. They are used to prevent moisture from entering the interior of the building. Poorly installed or missing flashing can result in damaging moisture leaks if the exterior is not sufficiently sealed.

- Misplaced Screws: In some cases, stray screws used for wood framing or struts may miss the mark and pierce the roof, creating an unexpected hole that can easily be overlooked.

How to Fix the Leak in Your Metal Roof

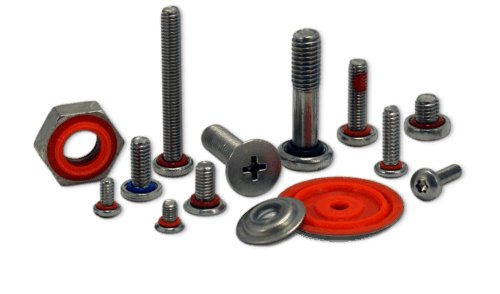

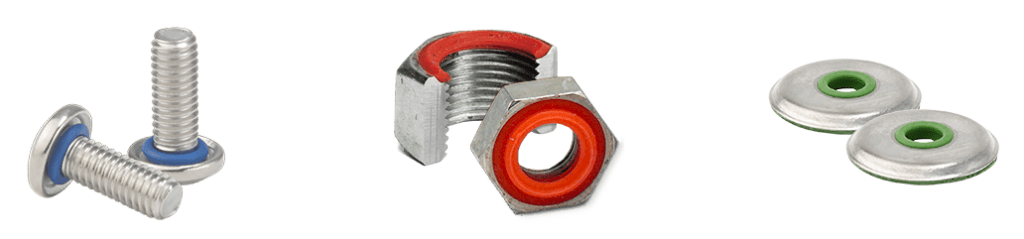

After installing a metal roof, it is critical to double-check your work to ensure all screws are properly installed. If your metal roof screws are leaking, it is important to take care of the issue as quickly as possible. Sealing metal roof leaks around screws with an external sealant may temporarily fix the issue, but surface sealant wears off over time. Instead, opt for sealing hardware such as APM Hexseal’s Seelskrews, Seelbolts, Seelnuts, and Seeloc Washers. Our stainless steel hardware features rubber-bonded threads and surfaces to serve the dual purpose of fastening and sealing. They will automatically seal metal roof leaks around screws without the need for additional sealing hardware or messy liquid sealants. For your installation and construction equipment, we also provide metal-to-rubber bonded washers, sealing boots, and bushing seals to protect your equipment controls.

Sealing Products From APM Hexseal

When your metal roof is leaking around the screws, APM Hexseal provides a variety of durable, corrosion-resistant sealing solutions. Our sealing hardware, boots, and bushing seals are specifically engineered for heavy-duty use in extreme conditions. Not only do our sealing fasteners help to eliminate existing roof leaks, but they also prevent future roof leaks.

When your metal roof is leaking around the screws, APM Hexseal provides a variety of durable, corrosion-resistant sealing solutions. Our sealing hardware, boots, and bushing seals are specifically engineered for heavy-duty use in extreme conditions. Not only do our sealing fasteners help to eliminate existing roof leaks, but they also prevent future roof leaks.

Sealing Hardware

APM Hexseal’s sealing hardware acts as both a fastener and a seal, so you can ensure the integrity of your metal roofing without the risk of leaks around the screws. Our selection of proprietary sealing hardware includes:

- Seelskrews® & Seelbolts®

- Seelnuts®

- Seeloc Washers®

Sealing Boots & Bushing Seals

In addition to our sealing fasteners, we offer a selection of molded sealing boots to protect electrical components, as well as quality bushing seals for switches and push-buttons.

Reach Out to Us Today!

Do you have questions about your metal roofing screws, or are you facing other sealing challenges? Ask the experts at APM Hexseal today!

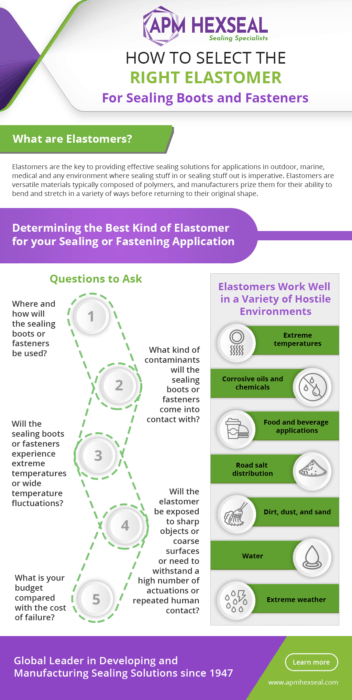

In the industrial sector, sealing hardware plays a critical role in ensuring components are securely fastened within a system and preventing contaminants—such as liquids and gases—from moving through the sealed area. Depending on the type of hardware—e.g., screws, nuts, bolts, and washers—and design employed, industry professionals can also take advantage of additional functions and features.

In the industrial sector, sealing hardware plays a critical role in ensuring components are securely fastened within a system and preventing contaminants—such as liquids and gases—from moving through the sealed area. Depending on the type of hardware—e.g., screws, nuts, bolts, and washers—and design employed, industry professionals can also take advantage of additional functions and features. At APM Hexseal, we understand that our customers often need more than a fastener for their industrial equipment. In addition to holding system components together, they require a solution that prevents process fluids—whether in gaseous or liquid form—from leaking in or out. As the first designer and manufacturer of self-sealing fasteners, we offer a number of patented solutions, including:

At APM Hexseal, we understand that our customers often need more than a fastener for their industrial equipment. In addition to holding system components together, they require a solution that prevents process fluids—whether in gaseous or liquid form—from leaking in or out. As the first designer and manufacturer of self-sealing fasteners, we offer a number of patented solutions, including: The next generation of leaders is taking the industrial sector to the next level with fresh ideas and a bold approach to modern challenges. These innovators are responsible for driving company and industry successes, and it’s important to honor their impact and influence. With that in mind, Thomas created the NextGen for Industry Award to

The next generation of leaders is taking the industrial sector to the next level with fresh ideas and a bold approach to modern challenges. These innovators are responsible for driving company and industry successes, and it’s important to honor their impact and influence. With that in mind, Thomas created the NextGen for Industry Award to  Susanna joined a multi-generational team at APM Hexseal, complete with a variety of opinions and levels of comfort regarding how the business operated. By creating an environment of innovation and collaboration, she made the changes she saw necessary if APM Hexseal was to continue to be a successful player in the sealing industry. Instead of trying to do everything at once, she made small, incremental changes—one or two at a time—as her team began to see her vision and trust her leadership.

Susanna joined a multi-generational team at APM Hexseal, complete with a variety of opinions and levels of comfort regarding how the business operated. By creating an environment of innovation and collaboration, she made the changes she saw necessary if APM Hexseal was to continue to be a successful player in the sealing industry. Instead of trying to do everything at once, she made small, incremental changes—one or two at a time—as her team began to see her vision and trust her leadership.

Many boats use our long-lasting, corrosion-resistant, and waterproof self-sealing boots and hardware to prevent moisture, salt and dust contamination to sensitive onboard equipment. Our sealing solutions allow you to easily use navigational and other electronic equipment come hell or high water.

Many boats use our long-lasting, corrosion-resistant, and waterproof self-sealing boots and hardware to prevent moisture, salt and dust contamination to sensitive onboard equipment. Our sealing solutions allow you to easily use navigational and other electronic equipment come hell or high water. Drones experience a variety of environmental and pressure extremes. Our products help prevent moisture and dirt contamination when drones are hundreds of feet in the air, and they naturally adapt to the changes in pressure and temperature that drones regularly experience.

Drones experience a variety of environmental and pressure extremes. Our products help prevent moisture and dirt contamination when drones are hundreds of feet in the air, and they naturally adapt to the changes in pressure and temperature that drones regularly experience. Snow blowers use sensitive electronics in cold and wet conditions. Our sealants help ensure that you will always be able to dig yourself out after a winter storm, as they prevent damage from occurring to the parts of the machines that shouldn’t contact snow, ice, sleet or salt!

Snow blowers use sensitive electronics in cold and wet conditions. Our sealants help ensure that you will always be able to dig yourself out after a winter storm, as they prevent damage from occurring to the parts of the machines that shouldn’t contact snow, ice, sleet or salt!