Types of Sealing Boots

In addition to pushbutton switches, sealing boots are also available for toggle and rotary type switches. Toggle switches are operated by a mechanical lever, rocking system, or handle (similar to a conventional light switch). Conversely, rotary switches are actuated by a rotating motion and can have two or more operating states. Each sealing boot is manufactured with features that facilitate the unique movement of each switch type.

Benefits of Using Pushbutton Boots

Hermetically sealed and standard unsealed pushbutton devices that operate under challenging environmental conditions require silicone boots to ensure maximum switch reliability and minimal maintenance and repair costs. Although ingress protection (IP) rated switches provide some degree of defense against the intrusion of foreign matter, they may not always supply an adequate safeguard due to their inherent vulnerabilities.

Moisture, salt, and cleaning solvents can penetrate the actuator mechanism and come into contact with internal contacts, resulting in corrosion or fungus buildup. Ice, dirt, and dust can accumulate on the actuator well and impede free movement of the switch. In addition, cleaning solutions and spilled liquids can seep past the mounting hole and travel down the bushing threads, negatively affecting the internal circuitry. These problems also exist in hermetically sealed pushbutton switches.

Pushbutton boots address these problems due to their single-piece construction, which protects all areas of the switch in even the most demanding environmental conditions. These boots also feature mounting nuts which encompass the base of the switch to create a full 360-degree airtight seal.

Pushbutton Boots Have Uses in Many Industries

Industries that perform switching operations in outdoor environments will see significant benefits when using weatherproof pushbutton switches. These include myriad sectors ranging from military and defense to home appliances. Pushbutton boots are also used to prevent the intrusion of foreign materials in sensitive equipment in the medical and pharmaceutical industries.

Some common applications of sealing boots include, but are not limited to:

- Instrumentation panels

- Communication switches

- Consumer electronics

- Heavy machinery control panels

- Control panels in aircraft and spacecraft

- Telecommunications network equipment

Sealing Solutions You Can Rely On

APM Hexseal manufactures sealing solutions for switches and circuit breakers for a wide variety of industries. Our products are designed to significantly extend the serviceable life of switches in some of world’s most challenging operational environments.

We offer a wide range of boots for the sealing of pushbutton switches of all styles and sizes. If you would like to know more about our sealing solutions and how they can protect your sensitive equipment, feel free to contact us or request a quote today. Our team is waiting to assist you in finding a sealing solution that fits the unique needs of your operation.

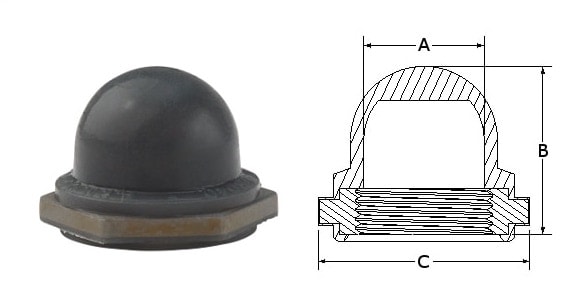

Pushbutton Boots with Hex-Shaped Insert

Material Specifications

For APM Hexseal® Standard Threaded Pushbutton Boots

- Mounting Nut:

- Brass, Nickel Plated

- Elastomer:

- Silicone conforms to A-A-59588, Class 3A, GR50 †, Gray ‡

- Temperature Range:

- -103° F to +400° F ( -75° C to +204° C)

- Resistant to:

- Splash, salt spray, sunlight, ozone, weather, fungus, dust, and most acids and lubricating oils.

- Shelf Life:

- Excess of 25 years.

† Durometer options available. Please contact APM Hexseal® for details.

‡ Additional color options available. Please contact APM Hexseal® for details.

| APM

Hexseal Part # |

Military

Part # |

Thread Size | Max Plunger Height

(Above

|

Internal

Diameter (A) |

Height (B) | Hex Size/Outer

Diameter (C) |

System of

Measurement |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1231/8 | - | 3/8-27 UNS-2B | 0.397" | 10.08mm | 0.300" | 7.62mm | 0.653" | 16.59mm | 0.500" | 12.70 mm | Imperial |

| 1231/35 | - | 3/8-32 UNEF-2B | 0.418" | 10.62mm | 0.300" | 7.62mm | 0.670" | 17.20mm | 0.500" | 12.70 mm | Imperial |

| 1231/51 | - | 3/8-27 UNS-2B | 0.665" | 16.88mm | 0.313" | 7.95mm | 0.875" | 22.23mm | 0.500" | 12.70 mm | Imperial |

| 1238/1 SS * | - | 15/32-32 UNS-2B | 0.306" | 7.77mm | 0.422" | 10.72mm | 1.008" | 25.60mm | 0.750" | 19.05mm | Imperial |

| N3030 | M5423/07-01 | 15/32-32 UNS-2B | 0.281" | 7.14mm | 0.422" | 10.72mm | 0.547" | 13.89mm | 0.625" | 15.88mm | Imperial |

| N3030 RFI † | M5423/07-06 | 15/32-32 UNS-2B | 0.281" | 7.14mm | 0.422" | 10.72mm | 0.547" | 13.89mm | 0.625" | 15.88mm | Imperial |

| N3040 | M5423/07-04 | 5/8-24 UNEF-2B | 0.281" | 7.14mm | 0.515" | 13.08mm | 0.609" | 15.47mm | 0.750" | 19.05mm | Imperial |

| N5040 | M5423/10-03 | 1/4-40 UNS-2B | 0.141" | 3.58mm | 0.188" | 4.78mm | 0.313" | 7.95mm | 0.375" | 9.53mm | Imperial |

| N5040G | M5423/10-01 | 1/4-32 UNEF-2B | 0.203" | 5.16mm | 0.188" | 4.78mm | 0.313" | 7.95mm | 0.375" | 9.53mm | Imperial |

| N5040R | M5423/10-02 | 1/4-40 UNS-2B | 0.203" | 5.16mm | 0.188" | 4.78mm | 0.313" | 7.95mm | 0.375" | 9.53mm | Imperial |

| N5045 | - | 8-40 UNS-2B | 0.188" | 4.78mm | 0.120" | 3.05mm | 0.297" | 7.54mm | 0.250" | 6.35mm | Imperial |

| NC3030 | M5423/07-02 | 15/32-32 UNS-2B | 0.438" | 11.13mm | 0.422" | 10.72mm | 0.719" | 18.26mm | 0.625" | 15.88mm | Imperial |

| NC3030 7/16-28 | - | 7/16-28 UNEF-2B | 0.438" | 11.13mm | 0.374" | 9.50mm | 0.719" | 18.26mm | 0.625" | 15.88mm | Imperial |

| NC3030FL ‡ | - | 15/32-32 UNS-2B | 0.520" | 13.21mm | 0.344" | 8.74mm | 0.797" | 20.24mm | 0.625" | 15.88mm | Imperial |

| NH3030 | M5423/07-03 | 1/2-32 UN-2B | 0.281" | 7.14mm | 0.422" | 10.72mm | 0.547" | 13.89mm | 0.625" | 15.88mm | Imperial |

| NC3030H M12x1 | - | M12 x 1 6H | 0.469" | 11.90mm | 0.422" | 10.72mm | 0.734" | 18.64mm | 0.625" | 15.88 mm | Metric |

For a full list of part numbers, please contact APM Hexseal.

* Armored Pushbutton Boot. (No image shown.) † Pushbutton Boot with EMI/RFI Shielding. (No image shown.) ‡ Flat Top Pushbutton Boot.

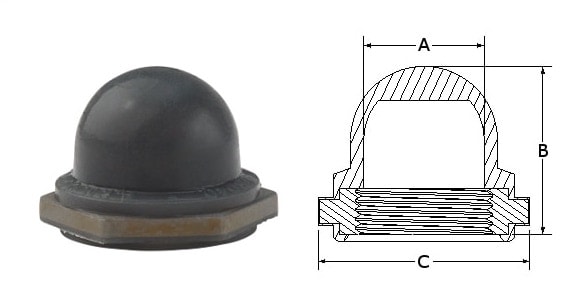

Pushbutton Boots with Round Insert

Material Specifications

For APM Hexseal® Standard Threaded Pushbutton Boots

- Mounting Nut:

- Brass, Nickel Plated

- Elastomer:

- Silicone conforms to A-A-59588, Class 3A, GR50 †, Gray ‡

- Temperature Range:

- -103° F to +400° F ( -75° C to +204° C)

- Resistant to:

- Splash, salt spray, sunlight, ozone, weather, fungus, dust, and most acids and lubricating oils.

- Shelf Life:

- Excess of 25 years.

† Durometer options available. Please contact APM Hexseal® for details.

‡ Additional color options available. Please contact APM Hexseal® for details.

| APM Hexseal

Part # |

Military

Part # |

Thread Size | Max Plunger Height

(Above Bushing) |

Internal

Diameter (A) |

Height (B) | Hex Size/Outer Diameter (C) | System of

Measurement |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C1221/22 | - | 3/8-24 UNF-2B | 0.330" | 8.40mm | 0.320" | 8.13mm | 0.609" | 15.47mm | 0.640" | 16.26mm | Imperial |

| C1221/24 ◆ | - | 3/8-27 UNS-2B | 0.419" | 10.64mm | 0.300" | 7.62mm | 0.609" | 15.47mm | 0.640" | 16.26mm | Imperial |

| C1221/25 | - | 3/8-27 UNS-2B | 0.419" | 10.64mm | 0.300" | 7.62mm | 0.609" | 15.47mm | 0.640" | 16.26mm | Imperial |

| C1221/21 M10 | - | M10 x 1 6H | 0.330" | 8.40mm | 0.320" | 8.13mm | 0.609" | 15.47mm | 0.640" | 16.26mm | Metric |

| C1221/27 | - | M11 x 1 6H | 0.267" | 6.78mm | 0.320" | 8.13mm | 0.609" | 15.47mm | 0.720" | 18.29mm | Metric |

For a full list of part numbers, please contact APM Hexseal.

◆Boot is made from APM Hexseal’s clear RUBRGLAS™

Pushbutton Boots with Hex-Shaped Insert

Material Specifications

For APM Hexseal® Standard Threaded Pushbutton Boots

- Mounting Nut:

- Brass, Nickel Plated

- Elastomer:

- Silicone conforms to A-A-59588, Class 3A, GR50 †, Gray ‡

- Temperature Range:

- -103° F to +400° F ( -75° C to +204° C)

- Resistant to:

- Splash, salt spray, sunlight, ozone, weather, fungus, dust, and most acids and lubricating oils.

- Shelf Life:

- Excess of 25 years.

† Durometer options available. Please contact APM Hexseal® for details.

‡ Additional color options available. Please contact APM Hexseal® for details.

| APM

Hexseal Part # |

Military

Part # |

Thread Size | Max Plunger Height

(Above

|

Internal

Diameter (A) |

Height (B) | Hex Size/Outer

Diameter (C) |

System of

Measurement |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1231/8 | - | 3/8-27 UNS-2B | 0.397" | 10.08mm | 0.300" | 7.62mm | 0.653" | 16.59mm | 0.500" | 12.70 mm | Imperial |

| 1231/35 | - | 3/8-32 UNEF-2B | 0.418" | 10.62mm | 0.300" | 7.62mm | 0.670" | 17.20mm | 0.500" | 12.70 mm | Imperial |

| 1231/51 | - | 3/8-27 UNS-2B | 0.665" | 16.88mm | 0.313" | 7.95mm | 0.875" | 22.23mm | 0.500" | 12.70 mm | Imperial |

| 1238/1 SS * | - | 15/32-32 UNS-2B | 0.306" | 7.77mm | 0.422" | 10.72mm | 1.008" | 25.60mm | 0.750" | 19.05mm | Imperial |

| N3030 | M5423/07-01 | 15/32-32 UNS-2B | 0.281" | 7.14mm | 0.422" | 10.72mm | 0.547" | 13.89mm | 0.625" | 15.88mm | Imperial |

| N3030 RFI † | M5423/07-06 | 15/32-32 UNS-2B | 0.281" | 7.14mm | 0.422" | 10.72mm | 0.547" | 13.89mm | 0.625" | 15.88mm | Imperial |

| N3040 | M5423/07-04 | 5/8-24 UNEF-2B | 0.281" | 7.14mm | 0.515" | 13.08mm | 0.609" | 15.47mm | 0.750" | 19.05mm | Imperial |

| N5040 | M5423/10-03 | 1/4-40 UNS-2B | 0.141" | 3.58mm | 0.188" | 4.78mm | 0.313" | 7.95mm | 0.375" | 9.53mm | Imperial |

| N5040G | M5423/10-01 | 1/4-32 UNEF-2B | 0.203" | 5.16mm | 0.188" | 4.78mm | 0.313" | 7.95mm | 0.375" | 9.53mm | Imperial |

| N5040R | M5423/10-02 | 1/4-40 UNS-2B | 0.203" | 5.16mm | 0.188" | 4.78mm | 0.313" | 7.95mm | 0.375" | 9.53mm | Imperial |

| N5045 | - | 8-40 UNS-2B | 0.188" | 4.78mm | 0.120" | 3.05mm | 0.297" | 7.54mm | 0.250" | 6.35mm | Imperial |

| NC3030 | M5423/07-02 | 15/32-32 UNS-2B | 0.438" | 11.13mm | 0.422" | 10.72mm | 0.719" | 18.26mm | 0.625" | 15.88mm | Imperial |

| NC3030 7/16-28 | - | 7/16-28 UNEF-2B | 0.438" | 11.13mm | 0.374" | 9.50mm | 0.719" | 18.26mm | 0.625" | 15.88mm | Imperial |

| NC3030FL ‡ | - | 15/32-32 UNS-2B | 0.520" | 13.21mm | 0.344" | 8.74mm | 0.797" | 20.24mm | 0.625" | 15.88mm | Imperial |

| NH3030 | M5423/07-03 | 1/2-32 UN-2B | 0.281" | 7.14mm | 0.422" | 10.72mm | 0.547" | 13.89mm | 0.625" | 15.88mm | Imperial |

| NC3030H M12x1 | - | M12 x 1 6H | 0.469" | 11.90mm | 0.422" | 10.72mm | 0.734" | 18.64mm | 0.625" | 15.88 mm | Metric |

For a full list of part numbers, please contact APM Hexseal.

* Armored Pushbutton Boot. (No image shown.) † Pushbutton Boot with EMI/RFI Shielding. (No image shown.) ‡ Flat Top Pushbutton Boot.

Pushbutton Boots with Round Insert

Material Specifications

For APM Hexseal® Standard Threaded Pushbutton Boots

- Mounting Nut:

- Brass, Nickel Plated

- Elastomer:

- Silicone conforms to A-A-59588, Class 3A, GR50 †, Gray ‡

- Temperature Range:

- -103° F to +400° F ( -75° C to +204° C)

- Resistant to:

- Splash, salt spray, sunlight, ozone, weather, fungus, dust, and most acids and lubricating oils.

- Shelf Life:

- Excess of 25 years.

† Durometer options available. Please contact APM Hexseal® for details.

‡ Additional color options available. Please contact APM Hexseal® for details.

| APM Hexseal

Part # |

Military

Part # |

Thread Size | Max Plunger Height

(Above Bushing) |

Internal

Diameter (A) |

Height (B) | Hex Size/Outer Diameter (C) | System of

Measurement |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C1221/22 | - | 3/8-24 UNF-2B | 0.330" | 8.40mm | 0.320" | 8.13mm | 0.609" | 15.47mm | 0.640" | 16.26mm | Imperial |

| C1221/24 ◆ | - | 3/8-27 UNS-2B | 0.419" | 10.64mm | 0.300" | 7.62mm | 0.609" | 15.47mm | 0.640" | 16.26mm | Imperial |

| C1221/25 | - | 3/8-27 UNS-2B | 0.419" | 10.64mm | 0.300" | 7.62mm | 0.609" | 15.47mm | 0.640" | 16.26mm | Imperial |

| C1221/21 M10 | - | M10 x 1 6H | 0.330" | 8.40mm | 0.320" | 8.13mm | 0.609" | 15.47mm | 0.640" | 16.26mm | Metric |

| C1221/27 | - | M11 x 1 6H | 0.267" | 6.78mm | 0.320" | 8.13mm | 0.609" | 15.47mm | 0.720" | 18.29mm | Metric |

For a full list of part numbers, please contact APM Hexseal.

◆Boot is made from APM Hexseal’s clear RUBRGLAS™