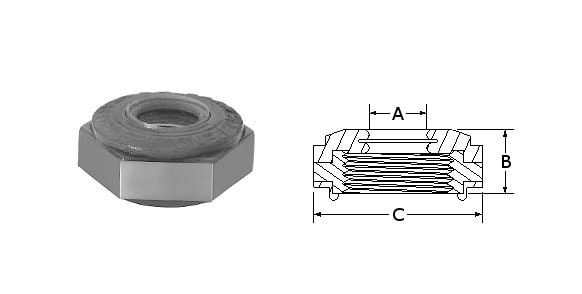

Material Specifications

For APM Hexseal® Standard Threaded Rotary Boots

- Mounting Nut:

- Brass, Nickel Plated

- Elastomer:

- Silicone conforms to A-A-59588, Class 3A, GR50 †, Gray ‡

- Temperature Range:

- -103° F to +400° F ( -75° C to +204° C)

- Resistant to:

- Splash, salt spray, sunlight, ozone, weather, fungus, dust, and most acids and lubricating oils.

- Shelf Life:

- Excess of 25 years.

† Durometer options available. Please contact APM Hexseal® for details. ‡ Additional color options available. Please contact APM Hexseal® for details.

| APM Hexseal

Part # |

Military

Part # |

Thread Size | Shaft Size (A) | Height (B) | Hex Size (C) | System of

Measurement |

|||

|---|---|---|---|---|---|---|---|---|---|

| N9030x1/4 | M5423/09-02 | 3/8-32 UNEF-2B | 0.250" | 6.35mm | 0.219" | 5.56mm | 0.500" | 12.70mm | Imperial |

| N9040x1/8 | M5423/09-03 | 1/4-32 UNEF-2B | 0.125" | 3.18mm | 0.219" | 5.56mm | 0.375" | 9.53mm | Imperial |

| N9042x1/8 | - | 1/4-28 UNF-2B | 0.125" | 3.18mm | 0.219" | 5.56mm | 0.375" | 9.53mm | Imperial |

| N9060x1/4 | M5423/09-04 | 15/32-32 UNS-2B | 0.250" | 6.35mm | 0.219" | 5.56mm | 0.625" | 15.88mm | Imperial |

| 1332/39 | - | M7x.75 6H | 0.196" | 5.00mm | 0.200" | 5.50mm | 0.500" | 12.70mm | Metric |

| 1332/45 | - | M10x1 6H | 0.236" | 6.00mm | 0.236" | 5.90mm | 0.500" | 12.70mm | Metric |

| 1332/46 | - | M10x.75 6H | 0.236" | 6.00mm | 0.236" | 5.90mm | 0.500" | 12.70mm | Metric |

| C1332/41 | - | M9x.75 6H | 0.250" | 6.35mm | 0.219" | 5.56mm | 0.500" | 12.70mm | Metric |

For a full list of part numbers, please contact APM Hexseal.

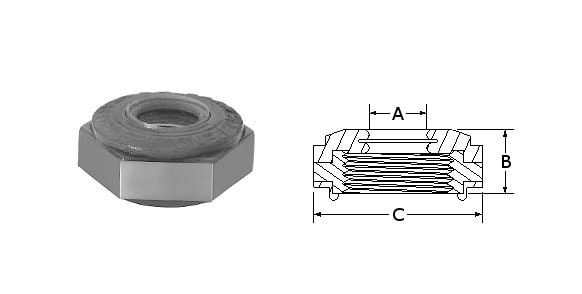

Material Specifications

For APM Hexseal® Standard Threaded Rotary Boots

- Mounting Nut:

- Brass, Nickel Plated

- Elastomer:

- Silicone conforms to A-A-59588, Class 3A, GR50 †, Gray ‡

- Temperature Range:

- -103° F to +400° F ( -75° C to +204° C)

- Resistant to:

- Splash, salt spray, sunlight, ozone, weather, fungus, dust, and most acids and lubricating oils.

- Shelf Life:

- Excess of 25 years.

† Durometer options available. Please contact APM Hexseal® for details. ‡ Additional color options available. Please contact APM Hexseal® for details.

| APM Hexseal

Part # |

Military

Part # |

Thread Size | Shaft Size (A) | Height (B) | Hex Size (C) | System of

Measurement |

|||

|---|---|---|---|---|---|---|---|---|---|

| N9030x1/4 | M5423/09-02 | 3/8-32 UNEF-2B | 0.250" | 6.35mm | 0.219" | 5.56mm | 0.500" | 12.70mm | Imperial |

| N9040x1/8 | M5423/09-03 | 1/4-32 UNEF-2B | 0.125" | 3.18mm | 0.219" | 5.56mm | 0.375" | 9.53mm | Imperial |

| N9042x1/8 | - | 1/4-28 UNF-2B | 0.125" | 3.18mm | 0.219" | 5.56mm | 0.375" | 9.53mm | Imperial |

| N9060x1/4 | M5423/09-04 | 15/32-32 UNS-2B | 0.250" | 6.35mm | 0.219" | 5.56mm | 0.625" | 15.88mm | Imperial |

| 1332/39 | - | M7x.75 6H | 0.196" | 5.00mm | 0.200" | 5.50mm | 0.500" | 12.70mm | Metric |

| 1332/45 | - | M10x1 6H | 0.236" | 6.00mm | 0.236" | 5.90mm | 0.500" | 12.70mm | Metric |

| 1332/46 | - | M10x.75 6H | 0.236" | 6.00mm | 0.236" | 5.90mm | 0.500" | 12.70mm | Metric |

| C1332/41 | - | M9x.75 6H | 0.250" | 6.35mm | 0.219" | 5.56mm | 0.500" | 12.70mm | Metric |

For a full list of part numbers, please contact APM Hexseal.