With a broad range of regulatory requirements and industry standards, sealing solution providers for the food and beverage industry must ensure that their products are of the highest quality and made to meet and exceed those standards. With more than 70 years of experience, APM Hexseal has the industry knowledge, qualifications, and certifications necessary to provide top quality sealing solutions for almost any food and beverage application.

Importance of Sealing Fasteners in the Food & Beverage Industry

The food and beverage industry requires a wide range of sealing solutions for everything from individual containers to processing and dispensing equipment. Seals ensure cleanliness and hygiene in compliance with various regulatory and industrial requirements. Quality sealing solutions also ensure product conformity and equipment durability. Adequate seals for processing and dispensing systems are also critical for the prevention of internal and external leakage that may result in equipment damage and product contamination.

Food & Beverage Industry Challenges

The food and beverage sector presents numerous challenges for sealing providers. The sheer variety of products, containers, equipment, and applications require an expansive range of creative solutions. Seals must avoid aroma transfer, prevent contamination, eliminate leaks, and fulfill industry hygiene standards while withstanding the extreme conditions present in processing operations.

- Avoiding aroma transfer. To maintain the integrity of food and beverage flavors and aromas, sealing solutions prevent the transfer of odors from one product to another during consecutive processing or packaging operations.

- Preventing contamination. Seals are key to preventing cross-contamination between products and external contamination from processing fluids, dust, moisture, and more.

- Leak prevention. Adequate sealing solutions help to prevent leakage that can cause loss of product, cross-contamination, and equipment damage.

- Hygienic standards. The hygienic standards of the food and beverage industry are extremely stringent, and sealing solutions must meet or exceed all industry regulations to ensure that products are safe for consumers.

- Extreme conditions. Food and beverage processing and packaging often expose dispensing, processing and manufacturing equipment to extreme temperatures, harsh cleaning solutions, greases and oils, and aromas. Sealing boots and hardware must withstand and protect against these conditions and continue to function within strict industry standards.

Examples of Food & Beverage Applications Using Sealing Solutions

APM Hexseal can provide sealing solutions that meet all requirements for food and beverage applications. Common applications for quality sealing solutions include:

Beverage Production

Beverage dispensing equipment is highly prone to leaks and must therefore be fitted with the best quality food and beverage sealing products. In addition to leak prevention, seals must be able to undergo extremely harsh chemical sanitization procedures to ensure adequate hygiene and prevent aroma transfer. Food grade silicone is perfect for these applications, as it is extremely durable, flexible, easily sanitized, and will not degrade when exposed to harsh chemicals.

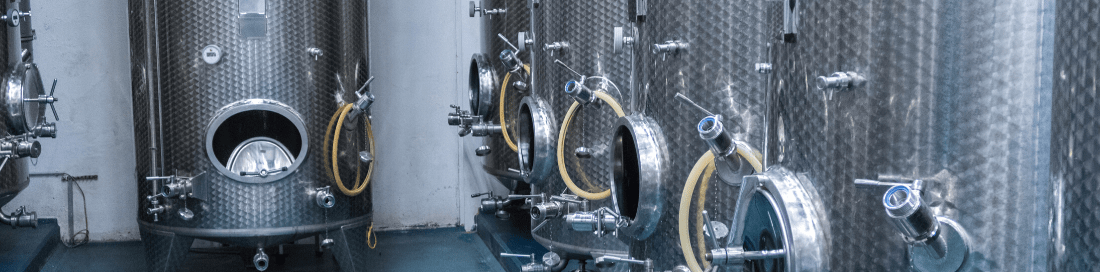

Brewing

Brewing encompasses a series of processes from barley milling, to fermentation, to bottling. Throughout brewing operations, seals contain harmful and abrasive malted barley dust and prevent the leakage of corrosive brewing and fermenting substances. Cleaning chemicals and high-temperature sterilization place even more strain on seals used for the brewing process, so it is particularly important that brewers use only the best quality sealing solutions.

Dairy Operations

Dairy operations are highly dependent on reliable seals that will withstand high temperatures and the extremely high fat content present in many dairy products. Fat from dairy products can collect in an inadequate or damaged seal, leaving the potential for dangerous product contamination. Extremely vigorous cleaning procedures prevent this type of contamination throughout the system, so seals must also be durable and capable of withstanding high pressures and corrosive cleaning chemicals.

Food Processing/Production

Food processing requires quality sealing technology to ensure the safe and reliable transfer of raw ingredients and completed food products of varying viscosities and textures. Food grade silicone offers an ideal material for seals on food processing equipment due to its ability to tolerate stringent cleaning procedures and washdowns. The inert nature of silicone also mitigates the risk of food product contamination.

Food Packaging

Since it is safe for contact with food, food grade silicone is frequently used to create seals on food packaging. For example, silicone gaskets provide tight seals on 5-gallon buckets and other food containers.

Advantages of APM Hexseal Sealing Solutions

At APM Hexseal, we pride ourselves on our ability to provide durable seals that protect your food and beverage operations from leakage and contamination. Our extensive line of sealing solutions offers the following advantages:

- Easy installation

- Reusable design

- Vibration and impact resistance

- Withstands intense internal and external pressure

- Customizable for specialized applications

APM Hexseal understands the need to maintain stringent quality controls, especially in the food and beverage industry. We maintain an extensive list of industry registrations and certifications so our customers know that they will always receive a product that meets or exceeds industry standards and regulations. Our certifications include:

- ISO 9001:2015

- Numerous UL-recognized components

- RoHS compliance

- REACH compliance

To see how our sealing solutions can improve the effectiveness of your food or beverage manufacturing operation, ask the experts at APM Hexseal today!