At APM Hexseal, we specialize in the design and manufacture of sealing solutions. Equipped with over 70 years of industry experience, we have the knowledge and skills to develop high-performance sealing solutions for even the most extreme and volatile environments. One of our core product offerings is sealing hardware.

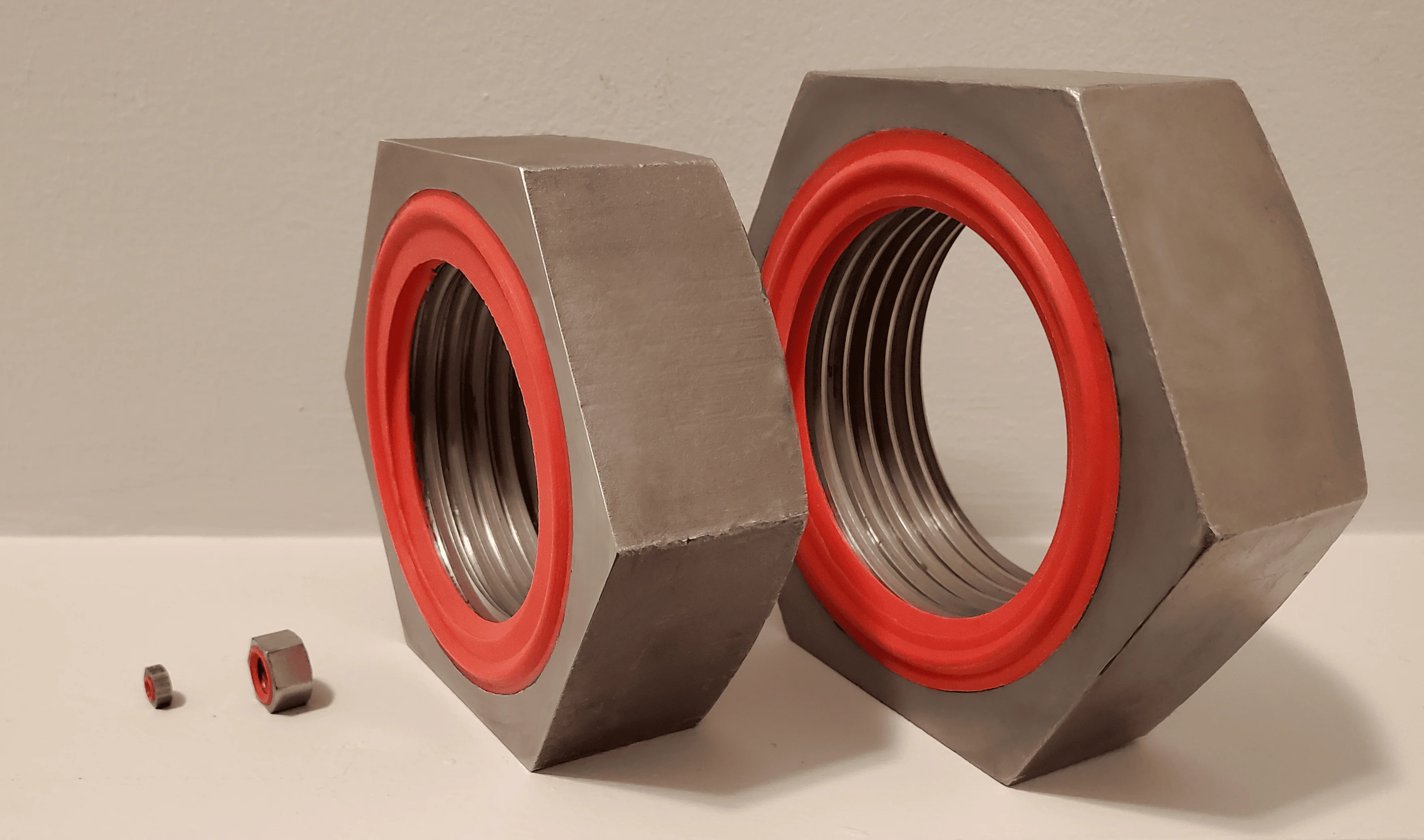

Sealing hardware has a dual purpose. It is designed to fasten two or more components together while preventing essential process fluids from escaping and contaminants from entering. As a result, it helps maintain the integrity of the process material and the performance of the system, which can lead to greater productivity, longer uptime, and smaller maintenance and repair costs.

The following provides an overview of sealing hardware, outlining APM Hexseal’s: