Celebrating a 75-year legacy

Leave a CommentWhat does it mean to be a 75-year-old, third-generation, family-owned American manufacturer? Some people might say that family-owned businesses don’t last that long — and are often mismanaged into bankruptcy. Well, at APM Hexseal, our 75th year was our best one ever. We made a lot of changes and investments in the business and our processes, and we are excited to see what the future holds for us.

The company was founded in 1947 by Milton and Riva Morse. They invented the sealing-fastener and switch boot technology, and Milton was awarded several patents for the products. In addition, he is an inductee into the New Jersey Inventors Hall of Fame. The company eventually passed on to his son, David Morse, and David’s wife, Carol. When David and Carol passed on, their daughter, Susanna Morse, assumed control of the business. We think she would say that it has been both exciting and terrifying — but overall, an exhilarating experience, being part of a 75-year successful legacy.

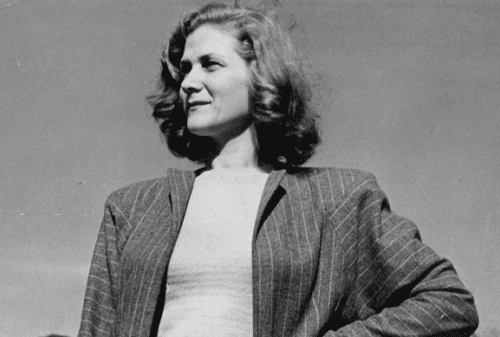

When the company was founded, Milton’s wife, Riva, assumed control of the sales functions. Milton was the inventor and Riva was the sales engine. At that point in time, it was unheard of for a woman to oversee sales for an engineering-based manufacturer, but that did not stop Riva from developing the strategies and framework for the sales channel that still, in large part, exist today. Milton and Riva would divorce, then re-marry, then divorce again — but throughout their personal strife, they remained respectful business partners and caring friends. They continued to keep their focus on APM Hexseal and making it a very successful endeavor. After Milton’s death, Riva continued to focus on the company, and even after her “retirement,” she would continue coming into the office each week to check on the business, say hello, and make sure she was visible to the employees. This continued until her death in 2018, just shy of her 101st birthday.

So how does a family-owned business survive everything the world throws at it for 75 years? You start with a well-designed and well-made product. We are the inventors of this product and, while there have been competitors who have imitated what we do, there will only ever be one original. One innovator. With that eye for innovation, we strive for continuous improvement and better ways to do things. We are dedicated to better products, better processes, and better and more efficient manufacturing methods. We are mindful of the importance of making things in the U.S., and that has been a driving factor since our inception.

We strive to provide excellent service to our customers and channel partners. Our goal is to deliver a top-quality product on time and at a fair price — and to do it with a superior level of service. We have an extensive global network of sales reps and distributors who also provide best-in-class support to our customers around the world. We are immensely proud of, and grateful to, our sales channel partners. We could not ship millions of parts to all corners of the world without their dedication.

The heart of any organization is its staff. Our employees are amazing, hard-working, and talented individuals who are completely committed to our quest to be ever better. They work tirelessly to make sure that our customers get what they need, when they need it. We have several employees who have been with us for more than 40 years. Even more have been here for 20 and 30+. That is not a coincidence. Companies cannot keep employees that long without providing a safe, fun, and productive work environment. We are a tight-knit family. We work together, laugh together, and sometimes we cry together — but always, we are there for each other. The Morse Family cares deeply about creating and keeping jobs here in the U.S., and we have strived to do that throughout our history. Our employees are our life’s blood, and we are eternally grateful for their dedication and hard work. We truly have the best team, and we are so proud of them.

At the end of the day, you must love what you do and go to work, every day, trying to do a better job than you did the day before. There will be imitators. There will be problems. There will be hiccups, roadblocks, loss, and strife. But you get back up and you keep going. You remember that one tough day does not erase one hundred great ones. You remember all the customers who say thank you. You remember all the problems you have helped customers to solve. You remember all the wonderful people you have met along the way. You remember that no matter what happens, we are a family and we are all working toward the same goals. You remember that making great products is what we do, and even after 75 years, we can always do better. That is what breeds excellence. That is what breeds longevity. That is what breeds innovation. That is what breeds success.

We are grateful for our history and for the dedicated employees, past and present, who have worked so hard to make this company a success. We are excited to see what is next and we look forward to the next 75 years!

- 75 years is Challenging.

- 75 years is Exhilarating.

- 75 years is Exciting.

- 75 years is Incredible.

- 75 years is Amazing.

- 75 years is APM Hexseal.

Ever Better.

Up until a month before she passed, Riva would still come in from time to time. She would walk through the office, wave to the people and spend a bit of time visiting. Smaller in stature but not at all diminished in status, she still radiated the smart, sassy and devoted woman who literally built the company. We miss seeing her but take sol

Up until a month before she passed, Riva would still come in from time to time. She would walk through the office, wave to the people and spend a bit of time visiting. Smaller in stature but not at all diminished in status, she still radiated the smart, sassy and devoted woman who literally built the company. We miss seeing her but take sol

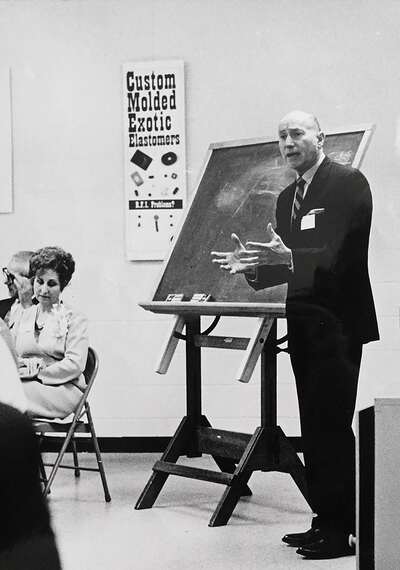

We have raised our internal quality standards and have engaged our entire staff in the pursuit of excellence. We have done several rounds of in-house employee quality training sessions, which will continue. In addition, we completed, and passed, our full ISO Audit, ISO 9001:2015 – our certificate can be found

We have raised our internal quality standards and have engaged our entire staff in the pursuit of excellence. We have done several rounds of in-house employee quality training sessions, which will continue. In addition, we completed, and passed, our full ISO Audit, ISO 9001:2015 – our certificate can be found

APM Hexseal products are perfect for green energy solutions (solar, wind, hydropower, etc.) because we design every part to protect sensitive electronics from the elements, meaning they are more durable and don’t need to be replaced as often. They are also ideal for use in the renewable energy sector due to their resilience in harsh weather conditions. Our parts are easy to recycle and reuse, so not only are they cost-efficient, they produce far less waste.

APM Hexseal products are perfect for green energy solutions (solar, wind, hydropower, etc.) because we design every part to protect sensitive electronics from the elements, meaning they are more durable and don’t need to be replaced as often. They are also ideal for use in the renewable energy sector due to their resilience in harsh weather conditions. Our parts are easy to recycle and reuse, so not only are they cost-efficient, they produce far less waste. Gasket vs. Washer: What’s the Difference?

Gasket vs. Washer: What’s the Difference?