What’s Right for Your Marine Applications?

Fasteners, such as screws, nuts, and bolts, are parts that hold materials together. While they are ubiquitous in many applications, traditional metal fasteners can be difficult to employ in the marine industry due to their tendency to corrode in saltwater environments.

To resolve this issue, APM Hexseal has developed a full line of sealing boots and hardware that demonstrate superior weather and corrosion resistance. These qualities make them ideal for use as marine fasteners in even the most demanding environments.

The Benefits of Our Sealing Fasteners

Compared to the alternatives available in the market, our sealing fasteners have several characteristics that make them more suitable for marine applications.

In addition to employing high quality raw materials, our sealing fasteners also feature our O-ring technology. This design element allows them to create a strong seal that prevents liquid and gases from getting in or out.

Our fasteners are also reusable—you can easily remove and reapply with the same sealing pressure when torqued. This quality makes them superior to traditional sealants, such as deformable washers and liquid thread sealers.

Our sealing hardware utilizes silicone rubber that is placed or molded into a specially formed groove and requires minimum compression and deformation when applying the desired torque. The result is reliable 360° metal-to-metal fastener contact with minimum friction, even over several installations.

The construction material is resistant to a variety of corrosive chemicals, making our fastener solutions perfect for operating in severe environments without the risk of seal degradation. Self-sealing fasteners can also have locking features, such as self-locking patches, pellets, and strips for additional vibrational resistance.

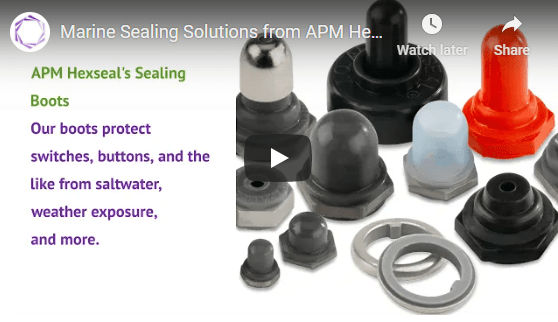

The Benefits of Our Sealing Boots

We manufacture a variety of different types of boots designed to protect various electronic components in marine systems, while still allowing the switch to actuate freely.

Circuit Breaker Boots

Our lever-actuated circuit breaker boots protect breakers from weather exposure, washings, salt water, lubricants, solvents, dust, dirt, grease, and more. Available in both front-of-panel and back-of-panel options, our circuit breaker boots employ our custom silicone material, RUBRGLAS®.

Toggle Boots

Available in full and half styles, our toggle boots include a sealing rib that keeps components securely attached to their mounting panels. These boots protect all types of toggle switches on fishing equipment and boat control panels. Our toggle boots consist of molded silicone placed over threaded mounting nuts allowing us to produce fully enclosed, single-piece components that cover the switch.

Pushbutton boots

Pushbutton boots are designed to provide push button switches protection against extreme environments or external elements, such as low or high temperatures, inclement weather, salt, dust, dirt, humidity, etc. that contribute to corrosion and other damages. Our pushbutton boots meet MIL-DTL-5423 specifications.

Sealing Solutions Designed to Combat Extreme Pressure

Our sealing solutions help facilitate the use of world-changing exploratory and energy-producing equipment in some of the harshest environments on Earth. Manufacturers of subsea products have long understood that using ordinary fasteners on robotics and sophisticated machinery intended for the ocean depths can be hazardous.

Self-sealing fasteners can be used to protect critical high-value subsea assets from the encroachment of saltwater in the highly pressurized underwater environment. In this way, sealing fasteners allow ocean-going and subsea robotics to withstand the harshest conditions while promoting the discovery of new insights and opportunities.

Ocean Exploration

Marine fasteners can protect valuable equipment, including sonar systems and advanced computers, from pressure damage and saltwater corrosion. They also safeguard inertial navigation systems that can be used to survey the bottom of the ocean for days at a time or trace meteorological conditions from the surface over longer periods. The information provided by these ocean exploration activities is critical to an accurate understanding of our atmosphere and resources.

Marine Energy Production

Our sealing screws can also be found on equipment that harvests wave energy for transfer to power grids, as well as ocean-going solar arrays used to power subsea exploration and information gathering.

Environmentally Friendly Protection

In addition to protecting equipment from the threat of damage by environmental hazards, sealing solutions can also prevent help safeguard ocean ecosystems by stopping the leakage of hazardous fluids and other chemicals into delicate and vulnerable aquatic ecosystems.

Request Your Standard or Custom Fasteners Today

APM Hexseal offers a number of sealing solutions ideal for use as marine fasteners due to their high corrosion resistance and unique sealing ability. Our sealing fasteners are integrated with embedded O-rings that compress when torqued. This compression causes the elastomeric O-ring material, typically silicone rubber, to distort and form an effective seal between mating surfaces, to seal contents in and the environment out.

Our patented sealing fasteners include Seelskrews®, Seelbolts®, Seelnuts®, and Seeloc® Washers which are designed to meet the needs of a variety of applications, including in the marine industry. In addition, we can customize products for more unique application requirements.

For more information on our marine industry sealing solutions or to get started on your next project, ask the experts at APM Hexseal today!