Fasteners often require additional sealing hardware to prevent leaks and ensure reliable, secure holds. APM Hexseal’s patented Seelskrews® and Seelbolts® combine dependable fastening hardware with weatherproof sealing materials. As a result, our self-sealing screws and bolts offer a reliable and reusable seal, preventing or containing contamination from dust, air, water, lubricants and other liquid or gaseous substances.

They are also vibration-resistant, making them a great choice for applications that encounter day-to-day jarring, or repetitive movement. Should you need a more serious level of vibration-resistance, our screws and bolts are available with additional locking features, such as self-locking pellets, strips, and patches.

Seelskrews and Seelbolts are available in many standard thread sizes and with various O-ring elastomer options. Some additional customizations include specialty thread-forming variations, tamper-resistant drives, thread captivation, and paint and finish options.

For information on maximum torque values for Seelskrews and Seelbolts, please see our table of Torque Values for Self-Sealing Hardware.

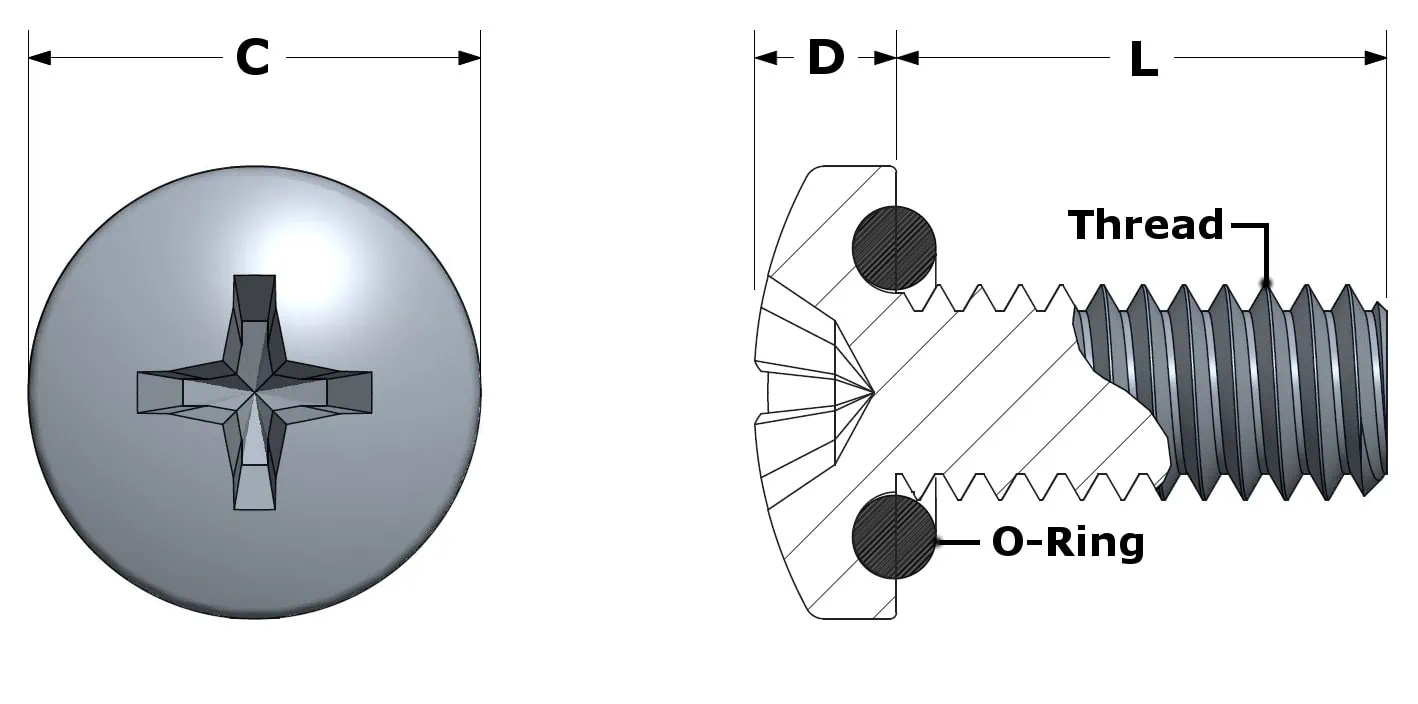

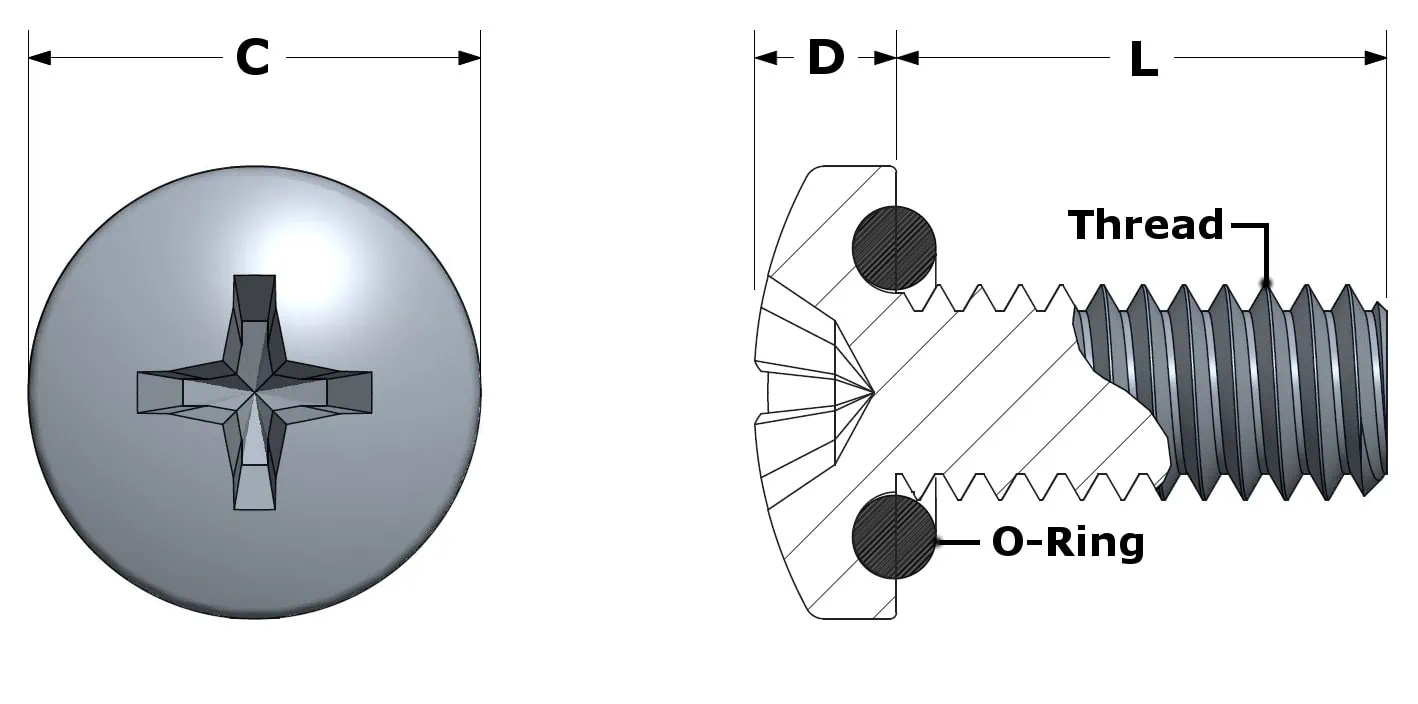

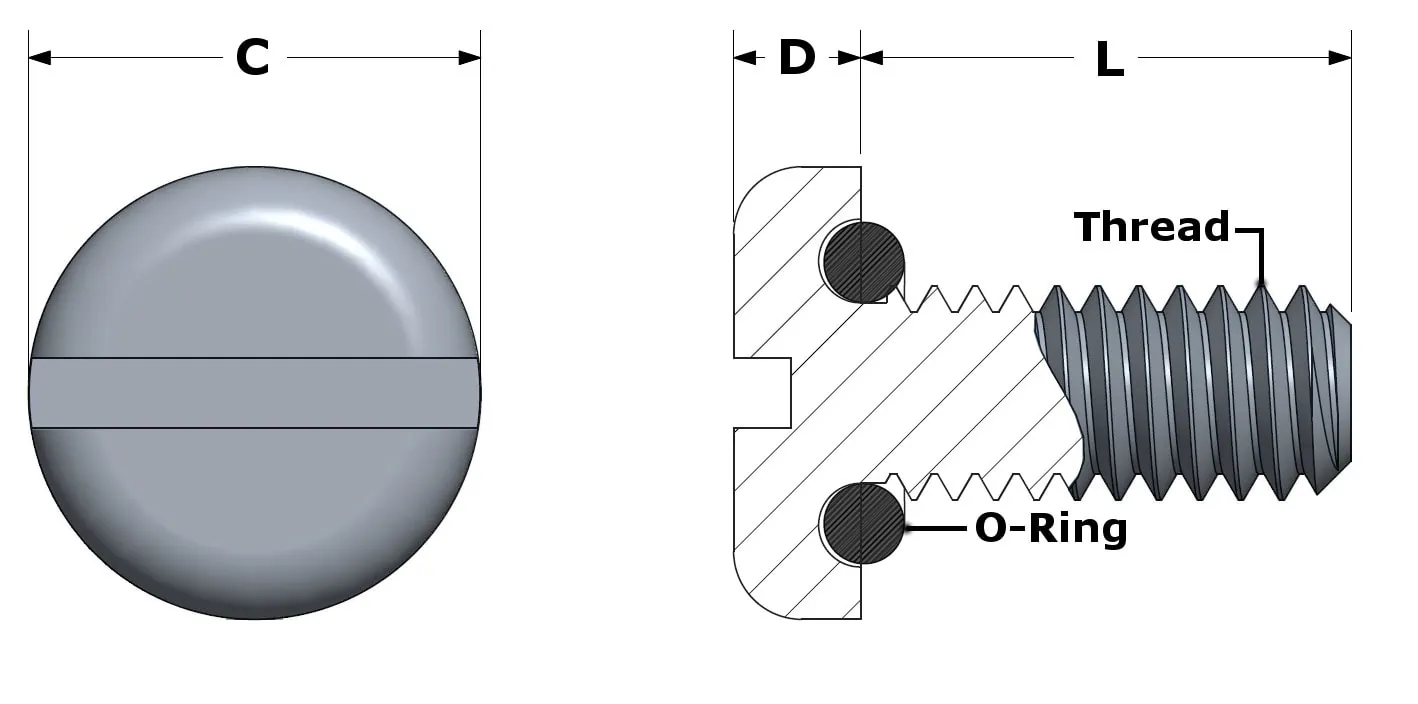

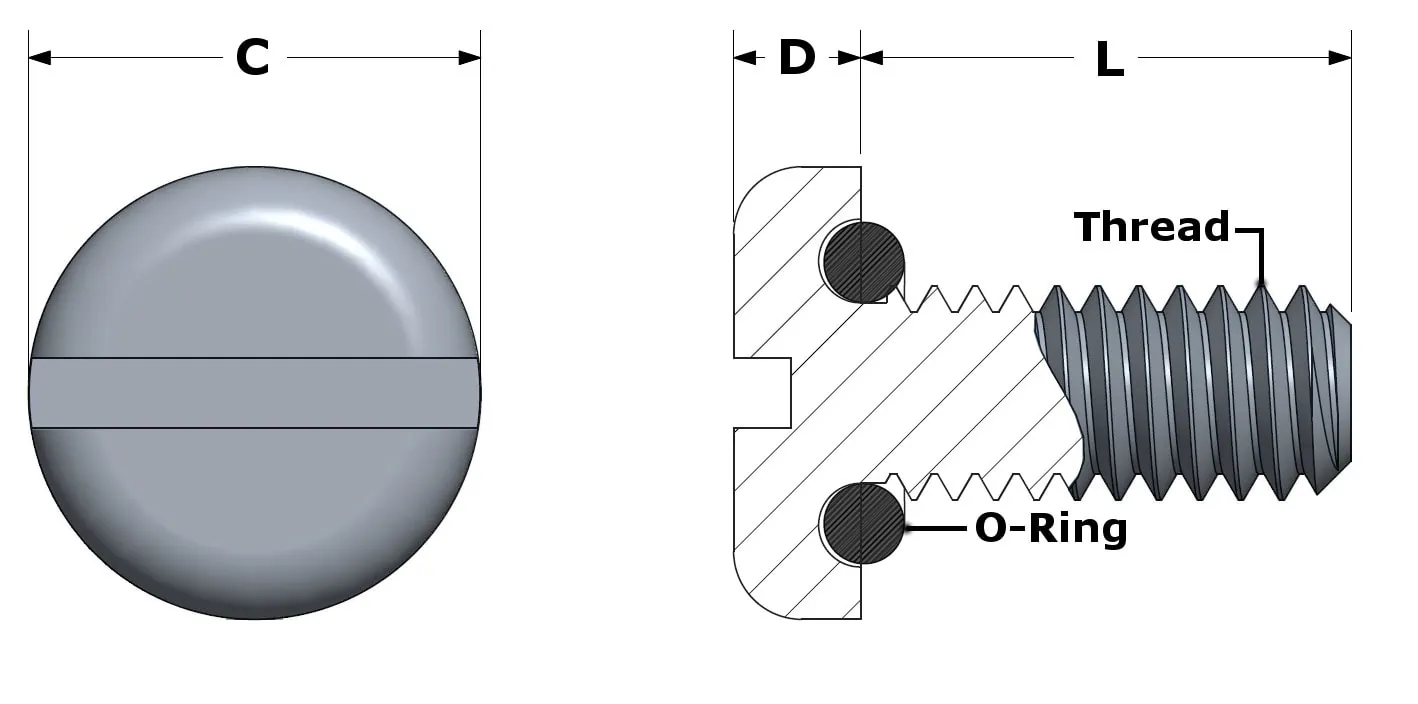

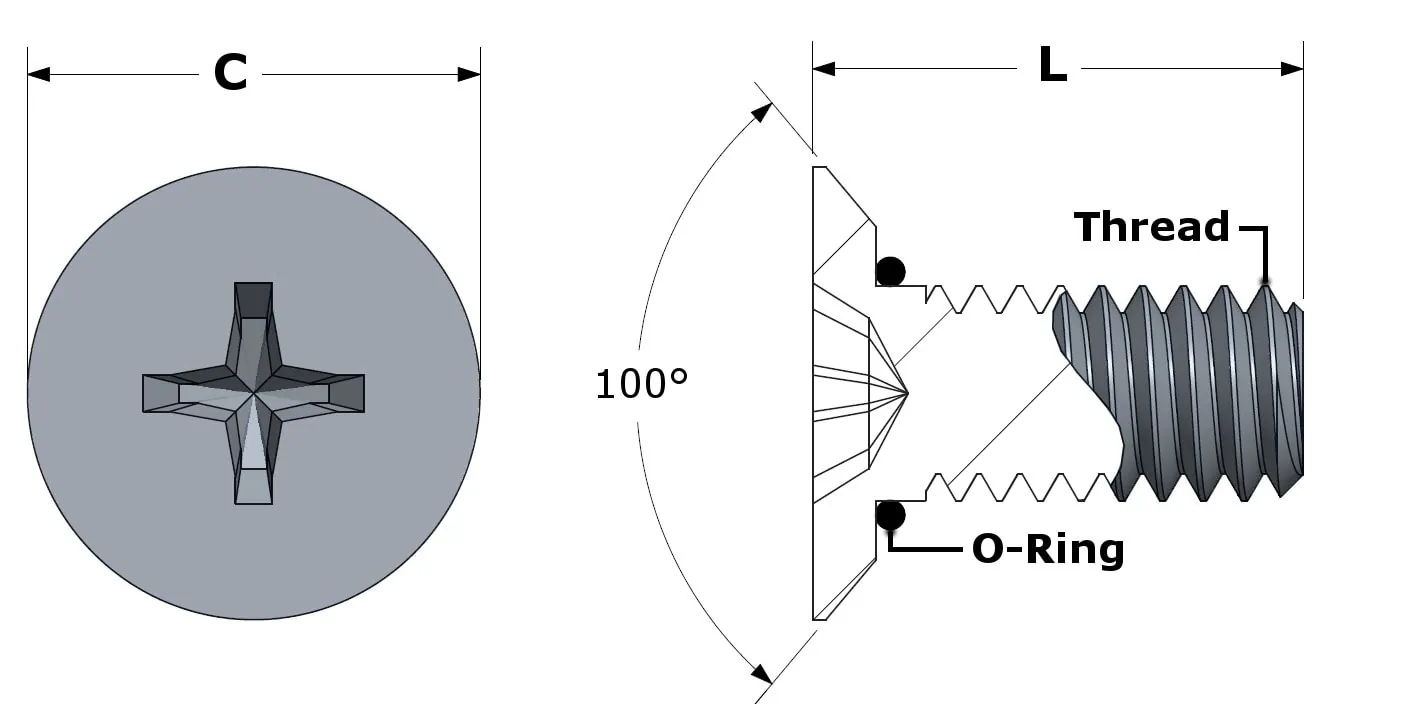

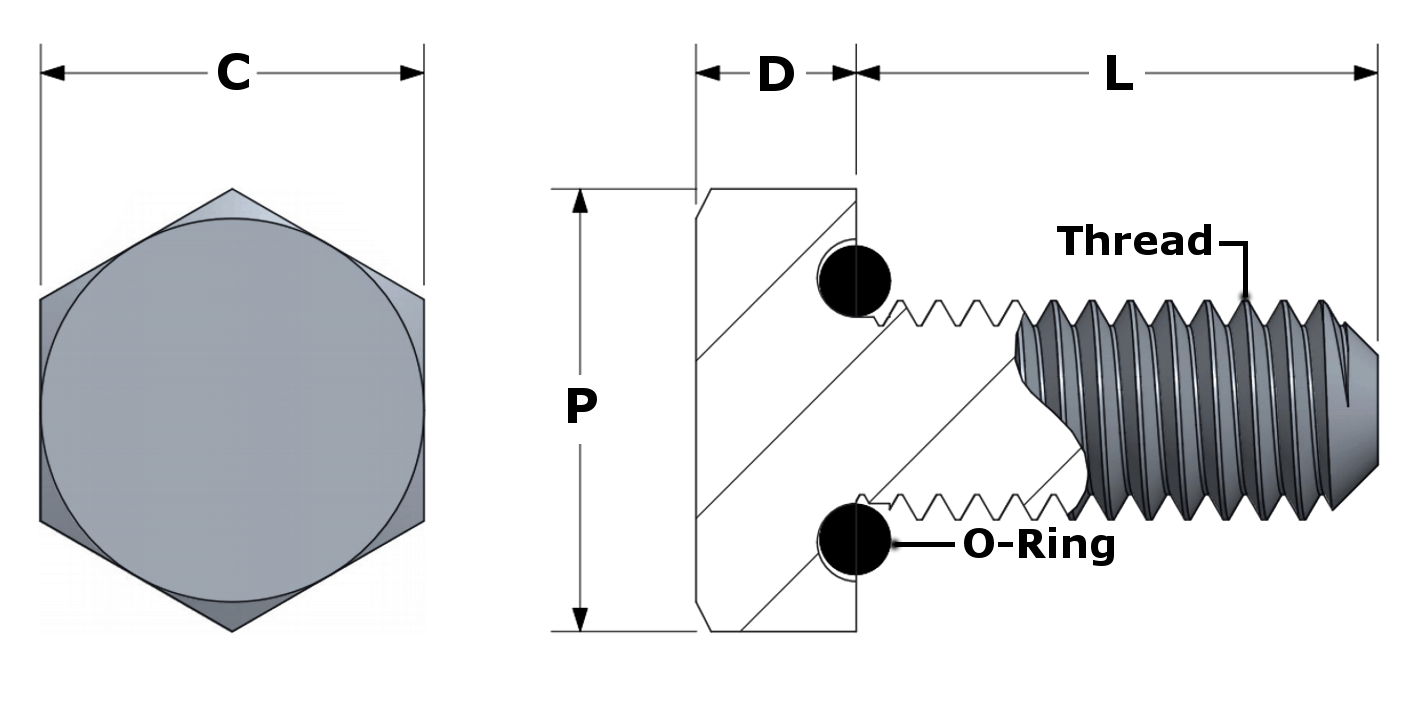

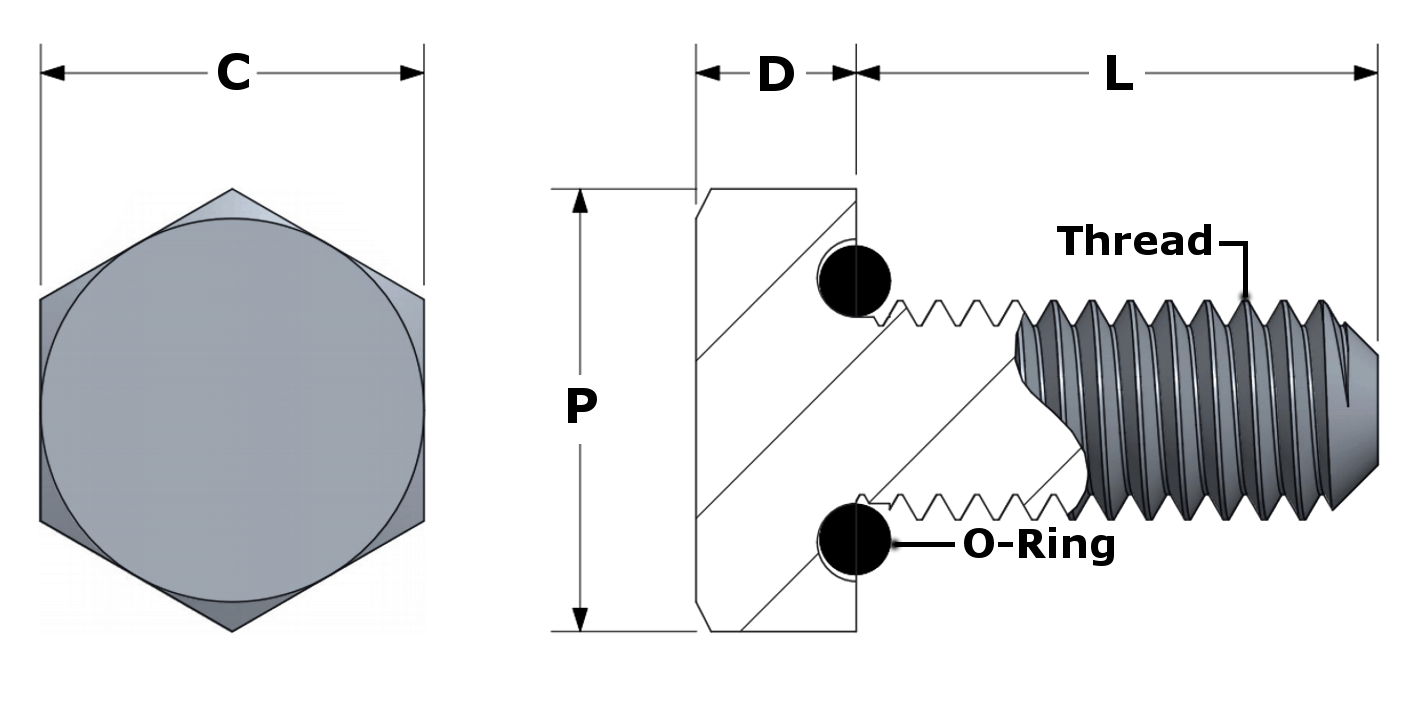

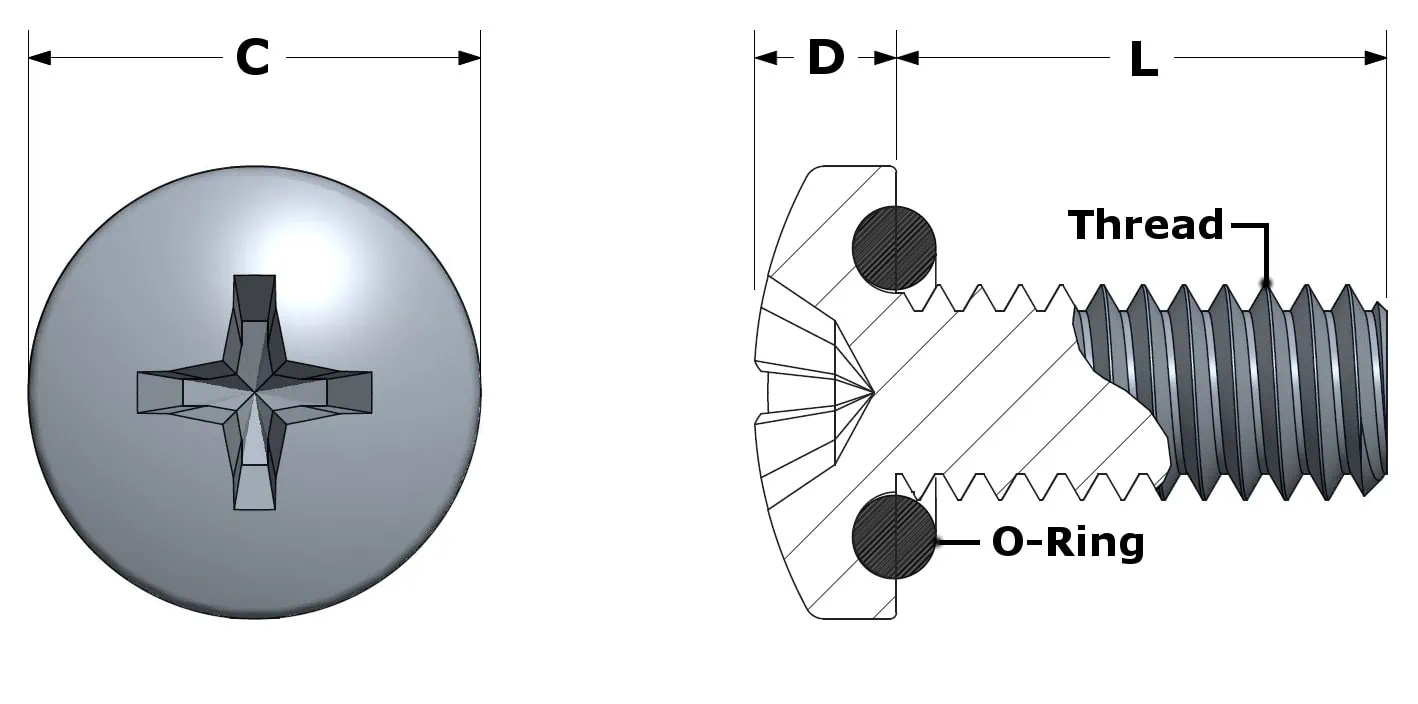

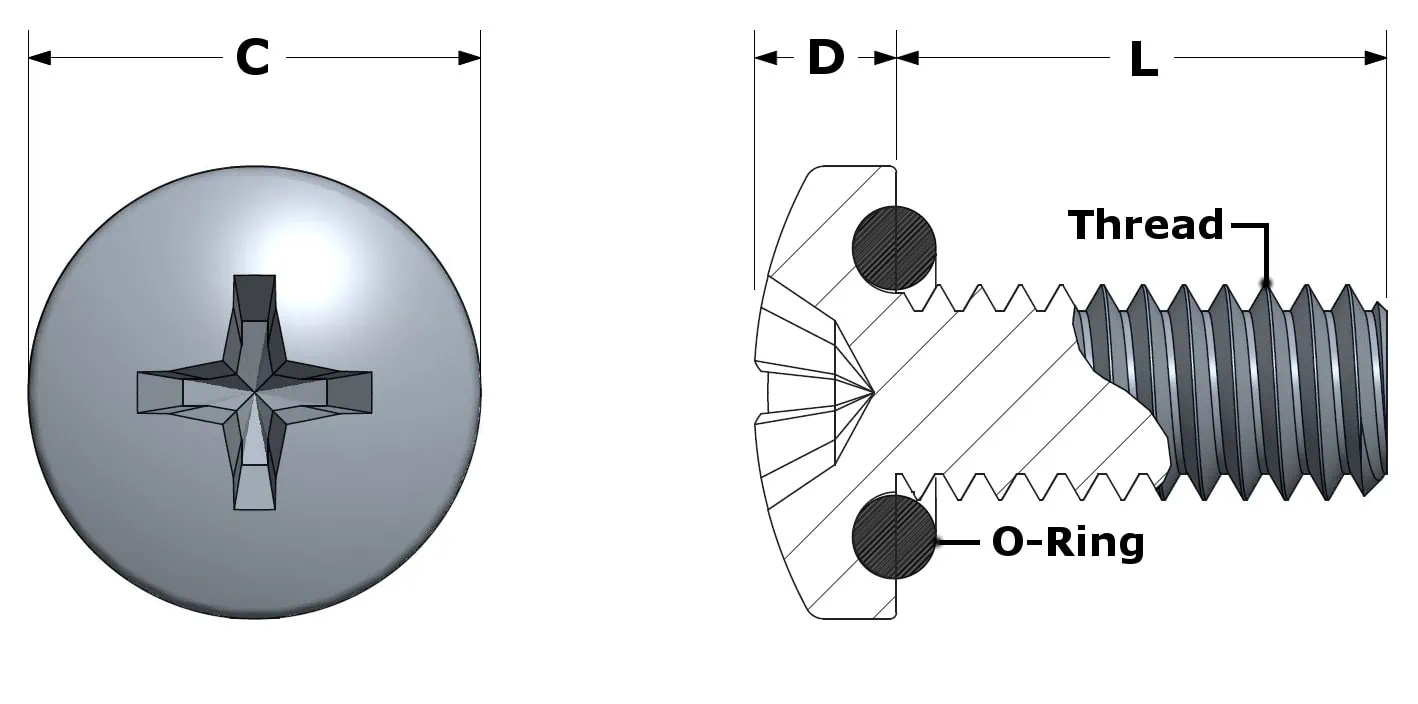

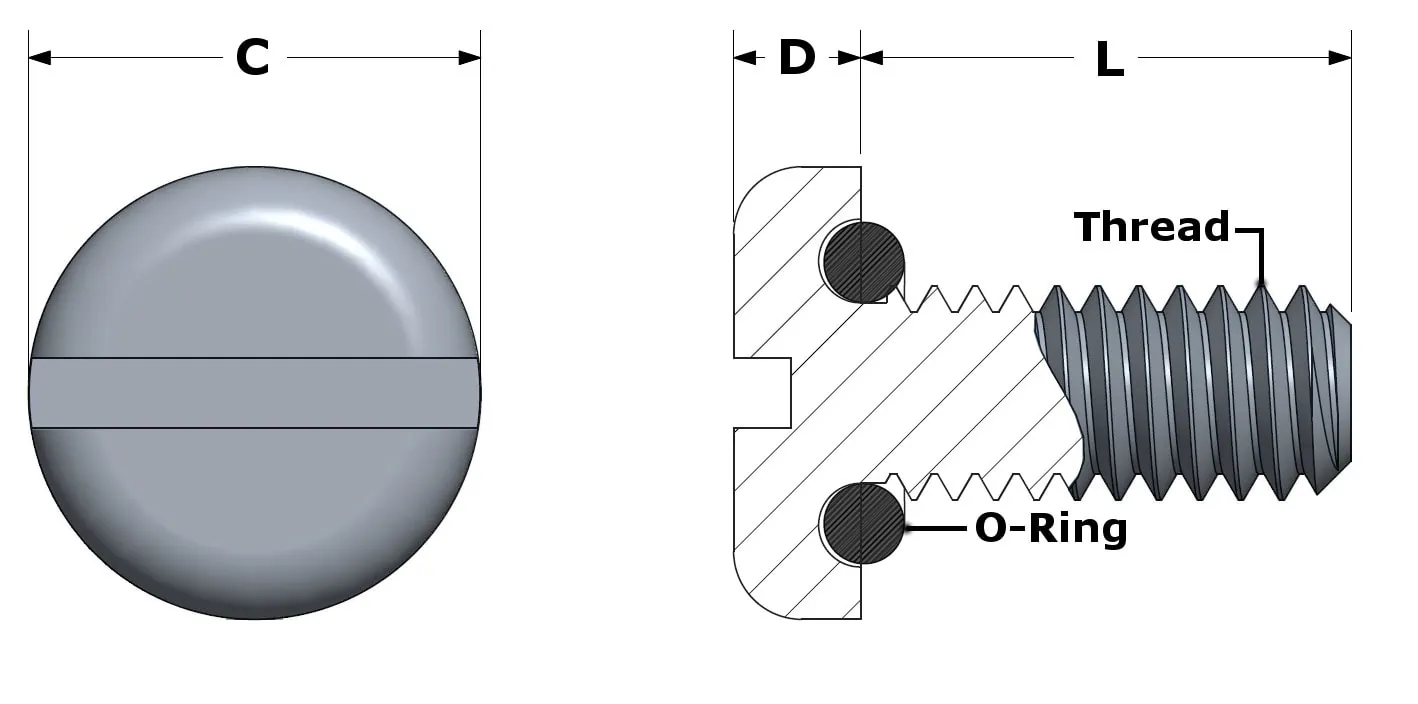

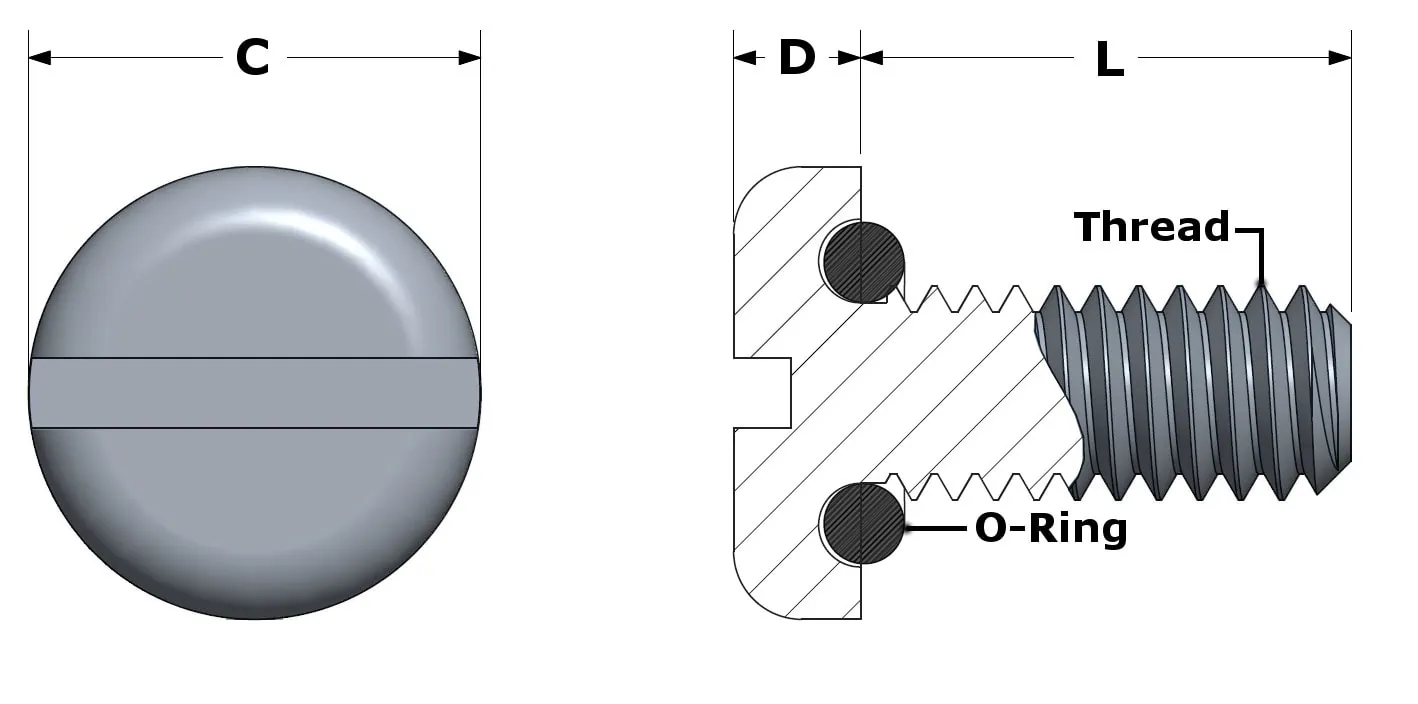

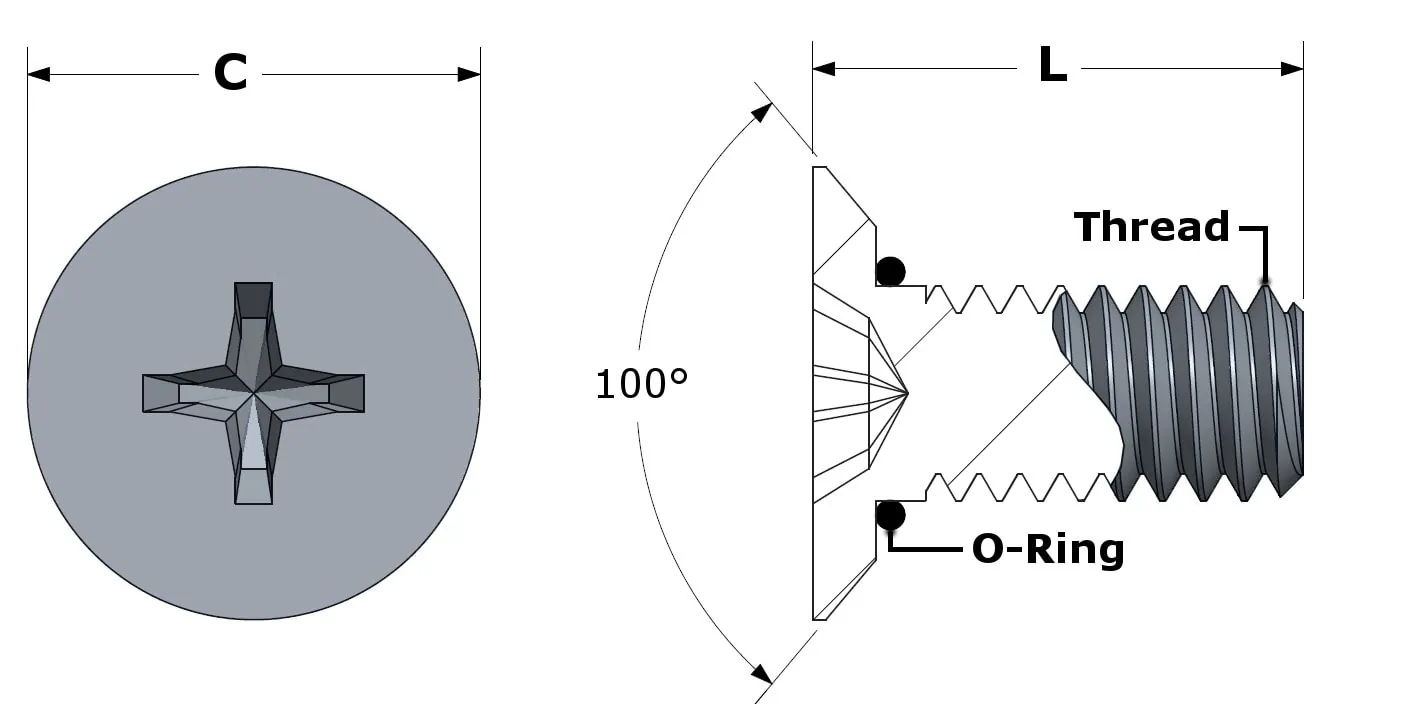

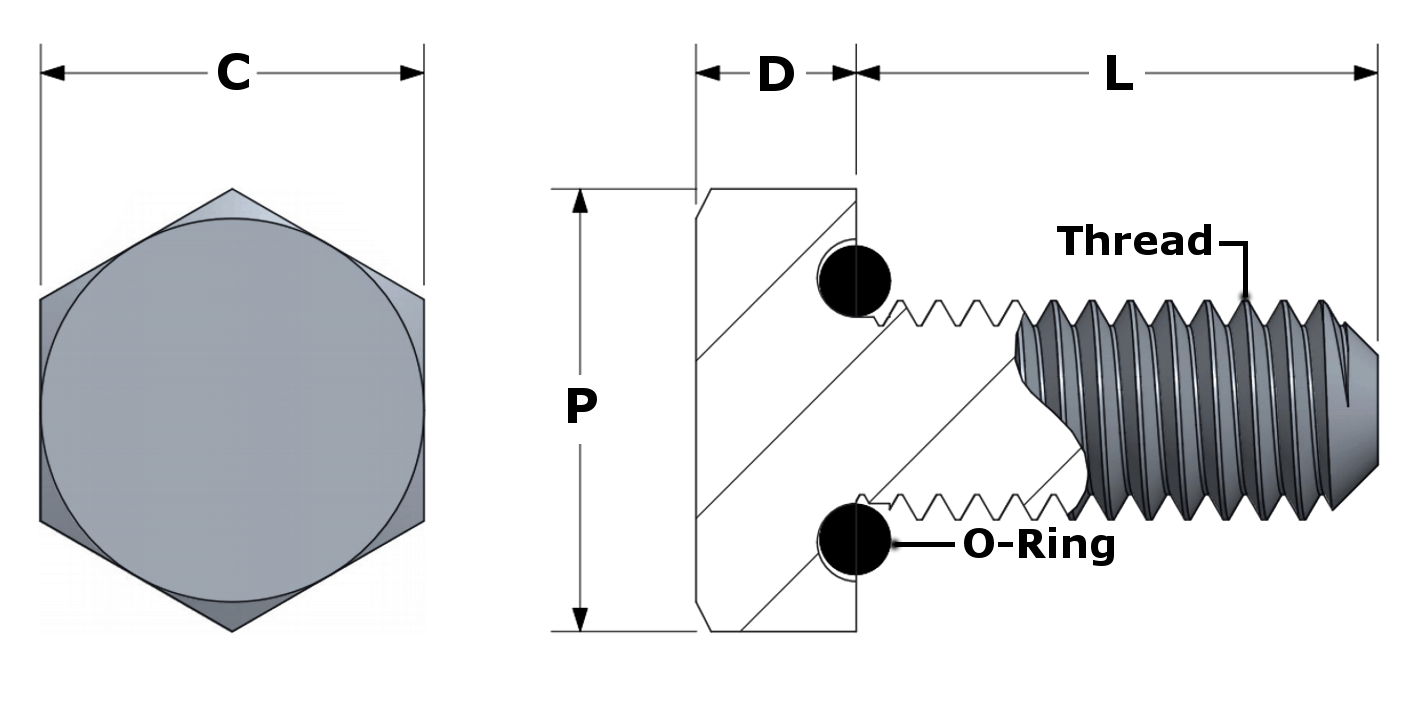

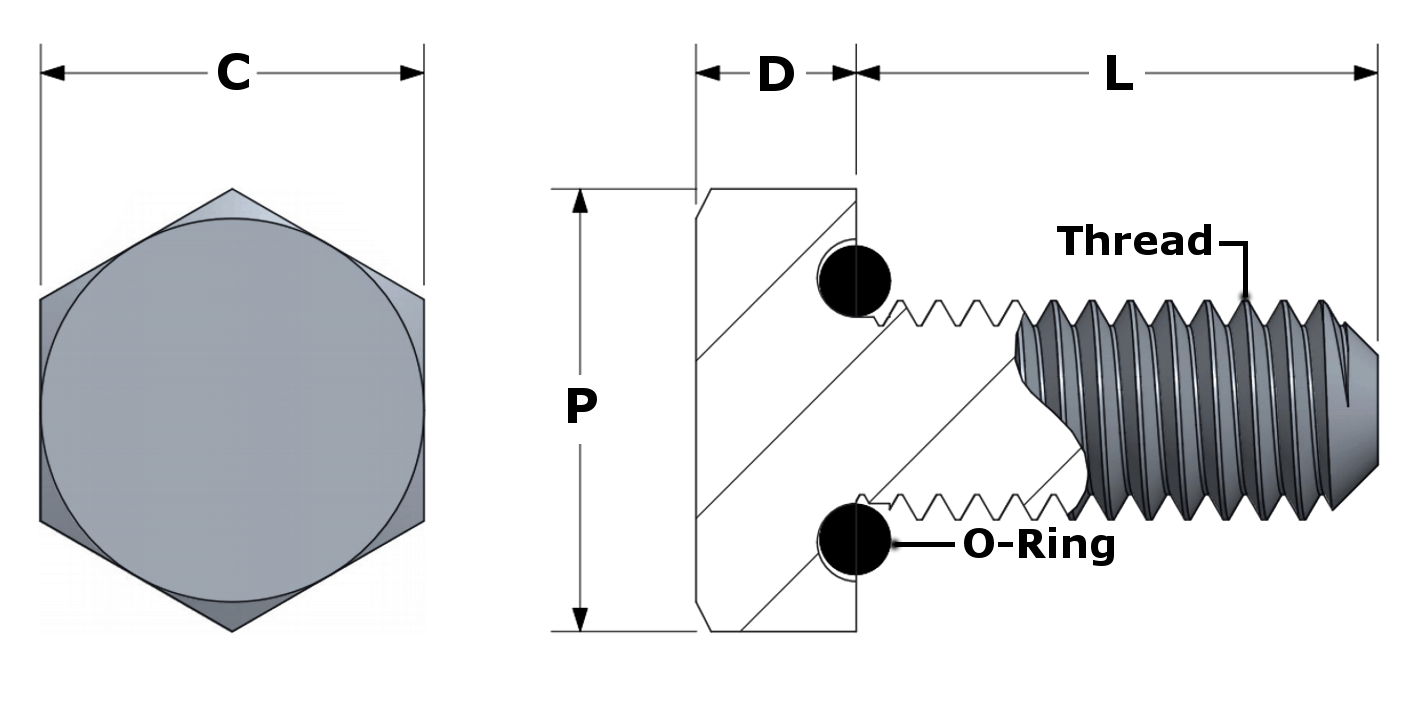

Anatomy of Seelskrews and Seelbolts

The anatomy of our Seelskrews and Seelbolts is simple, yet functional. We started the design with a stainless steel screw with an undercut head. The stainless steel provides a strong, corrosion-resistant base that’s ideal for fastening. A silicone O-ring is embedded in the groove under the screw’s head, creating a durable seal that resists moisture and corrosive chemicals.

Once fastened into the clearance hole, a Seelskrew or Seelbolt will offer 360° metal-on-metal contact when fully compressed. The Seelskrew or Seelbolt not only holds the component parts in place, but also helps to seal against intrusion from unwanted fluid, gas, and debris.

Features

APM Hexseal’s Seelskrews and Seelbolts offer a variety of unique features not shared by traditional fastening and sealing hardware, including:

- Positive seals while under pressure or vacuum conditions

- Easy installation

- Removeable and reusable

- Compatibility with all surface finishes

- Broad operating temperature range from -160°F to 500°F (-106°C to 260°C)

- Full 360° metal-to-metal contact for fastening integrity

- Uniform high-strength designs

- UL- and CSA-recognized

- Made in the USA

Types of Seelskrews® APM Hexseal Offers

We supply Seelskrew® sealing screws and Seelbolts® to manufacturers internationally, with options available in all standard metric sizes. Standard Seelskrews® come in 18.8 stainless steel with the ability to resist temperatures ranging from -80 °F (-62 °C) to 425 °F (219 °C). In addition, they are resistant to numerous potential contaminants and environmental elements that could otherwise cause wear and tear, including most oils and acids, dust, splash, fungus, salt spray, ozone, and ultraviolet light.

Design options include:

- Pan head with cross recess drive

- Flat head with cross recess drive

- Hexagonal head bolt

- Socket head cap screws

Materials

APM Hexseal produces Seelskrew® sealing screws with an O-ring using a variety of elastomers. While most of our self-sealing products use silicone for the elastomer component, we may use alternative elastomers like neoprene, fluorosilicone, or ethylene propylene diene terpolymer (EPDM). Our quality stainless steel screws and bolts are passivated and can be painted or coated to meet the particular requirements of nearly any application. Our representatives will discuss the needs of your project in detail and help you customize the ideal fastener design for your needs.

Our experts can help you make the right selection from the following based on your application’s requirements:

- Silicone. Applications requiring reliable heat resistance benefit from this material, with the ability to withstand continuous temperatures of up to 437 °F or intermittent temperatures as high as 500 °F.

- EPDM. This cost-effective material can resist heat, weather, and ozone, making it ideal for use in sealing washers for outdoor applications.

- Neoprene. This material is best for applications requiring resistance to aging, sunlight, chemicals, weathering, and ozone. It performs well in various joint sealing applications.

- Fluorosilicone. This material combines the properties of fluorocarbons and silicone, providing high heat and flame resistance, optimal low-temperature performance, and added resistance to elements like ozone, chemicals, water, and harsh weather.

Installation

Easy installation is one of the best things about our patented Seelskrews and Seelbolts. Simply screw the hardware into the pre-drilled mounting hole using your standard hand or power tools, the same way you would with a regular bolt or screw. As with standard fasteners, it is important to accurately measure your mounting hole and use the appropriately sized Seelbolt or Seelskrew for your application. When using a tool for installation, be sure to let your APM Hexseal representative know so they can offer advice about the best amount of torque for your material and fastener design.

Benefits of Sealing Screws

Here are some of the main advantages of using sealing screws from APM Hexseal:

Superior Sealing Performance

Seelskrews® create a 360º seal with an integrated sealing element and signature groove design that works to prevent contamination. Our sealing screws can block the entry of moisture, dust, and oil to maintain the integrity of seals and connected components.

Durable in Challenging Environments

The right sealing screws also resist corrosion and harsh weather conditions to give components the protection they need in nearly any environment, including those with extreme temperatures and high humidity levels.

At APM Hexseal, our sealing screws can also withstand high pressure levels, making them ideal for use in standard to extreme conditions.

Cost-Effective and Low Maintenance

Easily install our Seelskrew® sealing screws without any special equipment or preparation steps for near-instant integration. They require minimal maintenance after installation, reducing the need for frequent checking or replacement.

These components are also highly reusable to maximize their longevity.

Versatile and Customizable

Sealing screws offer a level of versatility that makes them compatible with many types of applications using various materials and designs. Choose from different head styles, sizes, and sealing materials to ensure they meet your specifications.

Reliable and Safe

Our Seelskrew® products help contain potentially harmful contaminants and prevent leakage with a reliable, durable seal. It’s also possible to engineer sealing screws to meet the quality standards of specific industries, enabling them to meet even the most stringent requirements.

Applications

Seelskrew® sealing screws work in many applications across a range of industries, including automotive, aerospace, agriculture, marine, construction, mining, and military. They also work with various mounting hole sizes and adjustment slots of many shapes. Remove and reuse these durable sealing screws for easy adjusting and maintenance.

Some of the systems that are most likely to implement Seelskrews® include:

- Underwater and nautical equipment

- Surface marine vehicles and equipment

- Sensitive instrumentation

- Medical equipment and devices

- Military ground equipment

- Off-road construction equipment

- Aviation and aerospace components

- Automotive components

- Robotics

- Electric, pneumatic, and hydraulic control systems

- Industrial fasteners for infrastructure

- Information and communication structures, cellular towers, and solar panels

In addition to the above, they can also be used to seal knockout holes in electrical housings, including cabinets and boxes.

APM Hexseal: Your Expert and Partner for Sealing Screw Needs

When looking for high-quality sealing hardware for components that need superior seals, get the solutions you need here at APM Hexseal. Whether you’re seeking standard or heavy-duty industrial sealing screws and bolts, you’ll find what you need from us as a top supplier of custom and standard solutions for nearly any application.

We also work toward continual improvement to stay on top of industry demands, meeting each customer’s unique requirements.

If you would like to discuss your sealing needs, ask an expert about our vast selection of products, or request a quote for your next solution.

- IMPERIAL PAN HEAD with CROSS RECESS DRIVE (PHILLIPS)

- METRIC PAN HEAD with CROSS RECESS DRIVE (PHILLIPS)

- IMPERIAL PAN HEAD with SLOTTED DRIVE

- METRIC PAN HEAD with SLOTTED DRIVE

- IMPERIAL FLAT HEAD with CROSS RECESS DRIVE (PHILLIPS)

- IMPERIAL HEXAGONAL HEAD BOLT

- METRIC HEXAGONAL HEAD BOLT

IMPERIAL PAN HEAD with CROSS RECESS DRIVE (PHILLIPS)

MATERIAL SPECIFICATIONS

For APM Hexseal® Standard Seelskrews® & Seelbolts®

- Screw Material:

- 18/8 Stainless Steel, passivated

- Threads:

- Imperial— Class 2A †; Metric— Class 6g

- O-Ring Elastomer:

- Silicone conforms to A-A-59588, Class 2, GR60 or GR70, Red ‡

- Temperature Range:

- -80° F to +425° F ( -62° C to +219° C)

- Resistant to:

- Splash, salt spray, sunlight, ozone, weather, fungus, dust, and most acids and lubricating oils.

† Standard for stock screws and bolts. ‡ Alternative o-ring elastomers are available. Consult our O-Ring Elastomer Options table for details.

| Thread Size | Drive Size | Min. Length

Available (L) |

Max. Head

Diameter (C) |

Max. Head

Height (D) |

Recommended Clearance

Hole (Min. - Max.) |

|---|---|---|---|---|---|

| 2-56 UNC-2A | #1 | 1/4" | 0.181" | 0.062" | 0.091" - 0.950" |

| 4-40 UNC-2A | #1 | 1/4" | 0.238" | 0.080" | 0.125" - 0.129" |

| 6-32 UNC-2A | #2 | 1/4" | 0.294" | 0.097" | 0.147" - 0.152" |

| 8-32 UNC-2A | #2 | 1/4" | 0.347" | 0.115" | 0.173" - 0.179" |

| 10-32 UNF-2A | #2 | 3/8" | 0.403" | 0.133" | 0.199" - 0.204" |

| 10-24 UNC-2A | #2 | 3/8" | 0.403" | 0.133" | 0.199" - 0.204" |

| 1/4-20 UNC-2A | #3 | 3/8" | 0.517" | 0.175" | 0.265" - 0.269" |

| 1/4-28 UNF-2A | #3 | 3/8" | 0.517" | 0.175" | 0.265" - 0.269" |

For a full list of part numbers, please contact APM Hexseal.

METRIC PAN HEAD with CROSS RECESS DRIVE (PHILLIPS)

MATERIAL SPECIFICATIONS

For APM Hexseal® Standard Seelskrews® & Seelbolts®

- Screw Material:

- 18/8 Stainless Steel, passivated

- Threads:

- Imperial— Class 2A †; Metric— Class 6g

- O-Ring Elastomer:

- Silicone conforms to A-A-59588, Class 2, GR60 or GR70, Red ‡

- Temperature Range:

- -80° F to +425° F ( -62° C to +219° C)

- Resistant to:

- Splash, salt spray, sunlight, ozone, weather, fungus, dust, and most acids and lubricating oils.

‡ Alternative o-ring elastomers are available. Consult our O-Ring Elastomer Options table for details.

| Thread Size | Drive Size | Min. Length

Available (L) |

Max. Head

Diameter (C) |

Max. Head

Height (D) |

Recommended Clearance

Hole (Min. - Max.) |

|---|---|---|---|---|---|

| M2 X 0.40 6g | #1 | 4mm | 4.24mm | 1.60mm | 2.31mm - 2.41mm |

| M2.5 X 0.45 6g | #1 | 4mm | 5.46mm | 2.10mm | 2.67mm - 2.84mm |

| M3 X 0.50 6g | #2 | 4mm | 6.70mm | 2.40mm | 3.55mm - 3.65mm |

| M4 X 0.70 6g | #2 | 4mm | 8.69mm | 3.05mm | 4.39mm - 4.54mm |

| M5 X 0.80 6g | #2 | 6mm | 9.90mm | 3.70mm | 5.56mm - 5.66mm |

| M6 X 1 6g | #3 | 6mm | 12.58mm | 4.60mm | 6.73mm - 6.83mm |

For a full list of part numbers, please contact APM Hexseal.

IMPERIAL PAN HEAD with SLOTTED DRIVE

MATERIAL SPECIFICATIONS

For APM Hexseal® Standard Seelskrews® & Seelbolts®

- Screw Material:

- 18/8 Stainless Steel, passivated

- Threads:

- Imperial— Class 2A †; Metric— Class 6g

- O-Ring Elastomer:

- Silicone conforms to A-A-59588, Class 2, GR60 or GR70, Red ‡

- Temperature Range:

- -80° F to +425° F ( -62° C to +219° C)

- Resistant to:

- Splash, salt spray, sunlight, ozone, weather, fungus, dust, and most acids and lubricating oils.

‡ Alternative o-ring elastomers are available. Consult our O-Ring Elastomer Options table for details.

| Thread Size | Min. Length

Available (L) |

Max. Head

Diameter (C) |

Max. Head

Height (D) |

Recommended Clearance

Hole (Min. - Max.) |

|---|---|---|---|---|

| 2-56 UNC-2A | 1/4" | 0.168" | 0.055" | 0.091" - 0.950" |

| 4-40 UNC-2A | 1/4" | 0.220" | 0.069" | 0.125" - 0.129" |

| 6-32 UNC-2A | 1/4" | 0.271" | 0.083" | 0.147" - 0.149" |

| 8-32 UNC-2A | 1/4" | 0.323" | 0.097" | 0.173" - 0.177" |

| 10-32 UNF-2A | 1/4" | 0.374" | 0.113" | 0.199" - 0.201" |

| 10-24 UNC-2A | 1/4" | 0.374" | 0.113" | 0.199" - 0.201" |

| 1/4-20 UNC-2A | 5/16" | 0.493" | 0.148" | 0.265" - 0.269" |

| 1/4-28 UNF-2A | 5/16" | 0.493" | 0.148" | 0.265" - 0.269" |

For a full list of part numbers, please contact APM Hexseal.

METRIC PAN HEAD with SLOTTED DRIVE

MATERIAL SPECIFICATIONS

For APM Hexseal® Standard Seelskrews® & Seelbolts®

- Screw Material:

- 18/8 Stainless Steel, passivated

- Threads:

- Imperial— Class 2A †; Metric— Class 6g

- O-Ring Elastomer:

- Silicone conforms to A-A-59588, Class 2, GR60 or GR70, Red ‡

- Temperature Range:

- -80° F to +425° F ( -62° C to +219° C)

- Resistant to:

- Splash, salt spray, sunlight, ozone, weather, fungus, dust, and most acids and lubricating oils.

‡ Alternative o-ring elastomers are available. Consult our O-Ring Elastomer Options table for details.

| Thread Size | Min. Length

Available (L) |

Max. Head

Diameter (C) |

Max. Head

Height (D) |

Recommended Clearance

Hole (Min. - Max.) |

|---|---|---|---|---|

| M2 x 0.40 6g | 4mm | 4.24mm | 1.37mm | 2.31mm - 2.41mm |

| M2.5 x 0.45 6g | 4mm | 5.56mm | 1.73mm | 2.67mm - 2.84mm |

| M3 x 0.50 6g | 4mm | 6.22mm | 1.90mm | 3.55mm - 3.65mm |

| M4 x 0.70 6g | 4mm | 8.17mm | 2.43mm | 4.39mm - 4.54mm |

| M5 x 0.80 6g | 6mm | 9.70mm | 3.05mm | 5.56mm - 5.66mm |

| M6 x 1 6g | 6mm | 12.49mm | 3.73mm | 6.73mm - 6.83mm |

| M8 x 1.25 6g | 6mm | 15.62mm | 4.52mm | 8.45mm - 8.55mm |

For a full list of part numbers, please contact APM Hexseal.

IMPERIAL FLAT HEAD with CROSS RECESS DRIVE (PHILLIPS)

MATERIAL SPECIFICATIONS

For APM Hexseal® Standard Seelskrews® & Seelbolts®

- Screw Material:

- 18/8 Stainless Steel, passivated

- Threads:

- Imperial— Class 2A †; Metric— Class 6g

- O-Ring Elastomer:

- Silicone conforms to A-A-59588, Class 2, GR60 or GR70, Red ‡

- Temperature Range:

- -80° F to +425° F ( -62° C to +219° C)

- Resistant to:

- Splash, salt spray, sunlight, ozone, weather, fungus, dust, and most acids and lubricating oils.

‡ Alternative o-ring elastomers are available. Consult our O-Ring Elastomer Options table for details.

| Thread Size | Drive Size | Min. Length Available (L) | Max. Head Diameter (C) | Recommended Clearance Hole (Min. - Max.) |

|---|---|---|---|---|

| 2-56 UNC-2A | #1 | 1/4" | 0.172" | 0.091" - 0.950" |

| 4-40 UNC-2A | #1 | 1/4" | 0.225" | 0.125" - 0.129" |

| 6-32 UNC-2A | #2 | 1/4" | 0.279" | 0.147" - 0.152" |

| 8-32 UNC-2A | #2 | 1/4" | 0.332" | 0.173" - 0.179" |

| 10-24 UNC-2A | #2 | 5/16" | 0.385" | 0.199" - 0.204" |

| 10-32 UNF-2A | #2 | 5/16" | 0.385" | 0.199" - 0.204" |

| 1/4-20 UNC-2A | #3 | 3/8" | 0.507" | 0.265" - 0.269" |

For a full list of part numbers, please contact APM Hexseal.

IMPERIAL HEXAGONAL HEAD BOLT

MATERIAL SPECIFICATIONS

For APM Hexseal® Standard Seelskrews® & Seelbolts®

- Bolt Material:

- 18/8 Stainless Steel, passivated

- Threads:

- Imperial— Class 2A †; Metric— Class 6g

- O-Ring Elastomer:

- Silicone conforms to A-A-59588, Class 2, GR60 or GR70, Red ‡

- Temperature Range:

- -80° F to +425° F ( -62° C to +219° C)

- Resistant to:

- Splash, salt spray, sunlight, ozone, weather, fungus, dust, and most acids and lubricating oils.

‡ Alternative o-ring elastomers are available. Consult our O-Ring Elastomer Options table for details.

| Thread Size | Min. Length Available (L) | Distance Between Flats (C) | Distance Between Points (P) † | Max. Head Height (D) | Recommended Clearance Hole (Min. - Max.) |

|---|---|---|---|---|---|

| 1/4-28 UNF-2A | 3/8" | 0.440" | 0.510" | 0.163" | 0.265" - 0.269" |

| 1/4-20 UNC-2A | 3/8" | 0.440" | 0.510" | 0.163" | 0.265" - 0.269" |

| 5/16-24 UNF-2A | 1/2" | 0.502" | 0.580" | 0.211" | 0.332" - 0.336" |

| 5/16-18 UNC-2A | 3/8" | 0.502" | 0.580" | 0.211" | 0.332" - 0.336" |

| 3/8-24 UNF-2A | 5/8" | 0.565" | 0.650" | 0.243" | 0.395" - 0.399" |

| 3/8-16 UNC-2A | 1/2" | 0.565" | 0.650" | 0.243" | 0.395" - 0.399" |

| 1/2-20 UNF-2A | 1/2" | 0.752" | 0.870" | 0.323" | 0.530" - 0.534" |

| 1/2-13 UNC-2A | 3/4" | 0.752" | 0.870" | 0.323" | 0.530" - 0.534" |

† The values provided for Distance Between Points are for reference only. |

|||||

For a full list of part numbers, please contact APM Hexseal.

METRIC HEXAGONAL HEAD BOLT

MATERIAL SPECIFICATIONS

For APM Hexseal® Standard Seelskrews® & Seelbolts®

- Bolt Material:

- 18/8 Stainless Steel, passivated

- Threads:

- Imperial— Class 2A †; Metric— Class 6g

- O-Ring Elastomer:

- Silicone conforms to A-A-59588, Class 2, GR60 or GR70, Red ‡

- Temperature Range:

- -80° F to +425° F ( -62° C to +219° C)

- Resistant to:

- Splash, salt spray, sunlight, ozone, weather, fungus, dust, and most acids and lubricating oils.

‡ Alternative o-ring elastomers are available. Consult our O-Ring Elastomer Options table for details.

| Thread Size | Min. Length Available (L) | Distance Between Flats (C) | Distance Between Points (P) † | Max. Head Height (D) | Recommended Clearance Hole (Min. - Max.) |

|---|---|---|---|---|---|

| M6 X 1 6g | 8mm | 10mm | 11.28mm | 4.15mm | 6.73mm - 6.83mm |

| M8 X 1.25 6g | 12mm | 13mm | 14.69mm | 5.65mm | 8.45mm - 8.55mm |

| M10 X 1.5 6g | 12mm | 17mm | 19.25mm | 7.18mm | 10.53mm - 10.64mm |

| M12 X 1.75 6g | 20mm | 19mm | 21.50mm | 8.18mm | 12.79mm - 12.9mm |

† The values provided for Distance Between Points are for reference only. |

|||||

For a full list of part numbers, please contact APM Hexseal.

IMPERIAL PAN HEAD with CROSS RECESS DRIVE (PHILLIPS)

MATERIAL SPECIFICATIONS

For APM Hexseal® Standard Seelskrews® & Seelbolts®

- Screw Material:

- 18/8 Stainless Steel, passivated

- Threads:

- Imperial— Class 2A †; Metric— Class 6g

- O-Ring Elastomer:

- Silicone conforms to A-A-59588, Class 2, GR60 or GR70, Red ‡

- Temperature Range:

- -80° F to +425° F ( -62° C to +219° C)

- Resistant to:

- Splash, salt spray, sunlight, ozone, weather, fungus, dust, and most acids and lubricating oils.

† Standard for stock screws and bolts. ‡ Alternative o-ring elastomers are available. Consult our O-Ring Elastomer Options table for details.

| Thread Size | Drive Size | Min. Length

Available (L) |

Max. Head

Diameter (C) |

Max. Head

Height (D) |

Recommended Clearance

Hole (Min. - Max.) |

|---|---|---|---|---|---|

| 2-56 UNC-2A | #1 | 1/4" | 0.181" | 0.062" | 0.091" - 0.950" |

| 4-40 UNC-2A | #1 | 1/4" | 0.238" | 0.080" | 0.125" - 0.129" |

| 6-32 UNC-2A | #2 | 1/4" | 0.294" | 0.097" | 0.147" - 0.152" |

| 8-32 UNC-2A | #2 | 1/4" | 0.347" | 0.115" | 0.173" - 0.179" |

| 10-32 UNF-2A | #2 | 3/8" | 0.403" | 0.133" | 0.199" - 0.204" |

| 10-24 UNC-2A | #2 | 3/8" | 0.403" | 0.133" | 0.199" - 0.204" |

| 1/4-20 UNC-2A | #3 | 3/8" | 0.517" | 0.175" | 0.265" - 0.269" |

| 1/4-28 UNF-2A | #3 | 3/8" | 0.517" | 0.175" | 0.265" - 0.269" |

For a full list of part numbers, please contact APM Hexseal.

METRIC PAN HEAD with CROSS RECESS DRIVE (PHILLIPS)

MATERIAL SPECIFICATIONS

For APM Hexseal® Standard Seelskrews® & Seelbolts®

- Screw Material:

- 18/8 Stainless Steel, passivated

- Threads:

- Imperial— Class 2A †; Metric— Class 6g

- O-Ring Elastomer:

- Silicone conforms to A-A-59588, Class 2, GR60 or GR70, Red ‡

- Temperature Range:

- -80° F to +425° F ( -62° C to +219° C)

- Resistant to:

- Splash, salt spray, sunlight, ozone, weather, fungus, dust, and most acids and lubricating oils.

‡ Alternative o-ring elastomers are available. Consult our O-Ring Elastomer Options table for details.

| Thread Size | Drive Size | Min. Length

Available (L) |

Max. Head

Diameter (C) |

Max. Head

Height (D) |

Recommended Clearance

Hole (Min. - Max.) |

|---|---|---|---|---|---|

| M2 X 0.40 6g | #1 | 4mm | 4.24mm | 1.60mm | 2.31mm - 2.41mm |

| M2.5 X 0.45 6g | #1 | 4mm | 5.46mm | 2.10mm | 2.67mm - 2.84mm |

| M3 X 0.50 6g | #2 | 4mm | 6.70mm | 2.40mm | 3.55mm - 3.65mm |

| M4 X 0.70 6g | #2 | 4mm | 8.69mm | 3.05mm | 4.39mm - 4.54mm |

| M5 X 0.80 6g | #2 | 6mm | 9.90mm | 3.70mm | 5.56mm - 5.66mm |

| M6 X 1 6g | #3 | 6mm | 12.58mm | 4.60mm | 6.73mm - 6.83mm |

For a full list of part numbers, please contact APM Hexseal.

IMPERIAL PAN HEAD with SLOTTED DRIVE

MATERIAL SPECIFICATIONS

For APM Hexseal® Standard Seelskrews® & Seelbolts®

- Screw Material:

- 18/8 Stainless Steel, passivated

- Threads:

- Imperial— Class 2A †; Metric— Class 6g

- O-Ring Elastomer:

- Silicone conforms to A-A-59588, Class 2, GR60 or GR70, Red ‡

- Temperature Range:

- -80° F to +425° F ( -62° C to +219° C)

- Resistant to:

- Splash, salt spray, sunlight, ozone, weather, fungus, dust, and most acids and lubricating oils.

‡ Alternative o-ring elastomers are available. Consult our O-Ring Elastomer Options table for details.

| Thread Size | Min. Length

Available (L) |

Max. Head

Diameter (C) |

Max. Head

Height (D) |

Recommended Clearance

Hole (Min. - Max.) |

|---|---|---|---|---|

| 2-56 UNC-2A | 1/4" | 0.168" | 0.055" | 0.091" - 0.950" |

| 4-40 UNC-2A | 1/4" | 0.220" | 0.069" | 0.125" - 0.129" |

| 6-32 UNC-2A | 1/4" | 0.271" | 0.083" | 0.147" - 0.149" |

| 8-32 UNC-2A | 1/4" | 0.323" | 0.097" | 0.173" - 0.177" |

| 10-32 UNF-2A | 1/4" | 0.374" | 0.113" | 0.199" - 0.201" |

| 10-24 UNC-2A | 1/4" | 0.374" | 0.113" | 0.199" - 0.201" |

| 1/4-20 UNC-2A | 5/16" | 0.493" | 0.148" | 0.265" - 0.269" |

| 1/4-28 UNF-2A | 5/16" | 0.493" | 0.148" | 0.265" - 0.269" |

For a full list of part numbers, please contact APM Hexseal.

METRIC PAN HEAD with SLOTTED DRIVE

MATERIAL SPECIFICATIONS

For APM Hexseal® Standard Seelskrews® & Seelbolts®

- Screw Material:

- 18/8 Stainless Steel, passivated

- Threads:

- Imperial— Class 2A †; Metric— Class 6g

- O-Ring Elastomer:

- Silicone conforms to A-A-59588, Class 2, GR60 or GR70, Red ‡

- Temperature Range:

- -80° F to +425° F ( -62° C to +219° C)

- Resistant to:

- Splash, salt spray, sunlight, ozone, weather, fungus, dust, and most acids and lubricating oils.

‡ Alternative o-ring elastomers are available. Consult our O-Ring Elastomer Options table for details.

| Thread Size | Min. Length

Available (L) |

Max. Head

Diameter (C) |

Max. Head

Height (D) |

Recommended Clearance

Hole (Min. - Max.) |

|---|---|---|---|---|

| M2 x 0.40 6g | 4mm | 4.24mm | 1.37mm | 2.31mm - 2.41mm |

| M2.5 x 0.45 6g | 4mm | 5.56mm | 1.73mm | 2.67mm - 2.84mm |

| M3 x 0.50 6g | 4mm | 6.22mm | 1.90mm | 3.55mm - 3.65mm |

| M4 x 0.70 6g | 4mm | 8.17mm | 2.43mm | 4.39mm - 4.54mm |

| M5 x 0.80 6g | 6mm | 9.70mm | 3.05mm | 5.56mm - 5.66mm |

| M6 x 1 6g | 6mm | 12.49mm | 3.73mm | 6.73mm - 6.83mm |

| M8 x 1.25 6g | 6mm | 15.62mm | 4.52mm | 8.45mm - 8.55mm |

For a full list of part numbers, please contact APM Hexseal.

IMPERIAL FLAT HEAD with CROSS RECESS DRIVE (PHILLIPS)

MATERIAL SPECIFICATIONS

For APM Hexseal® Standard Seelskrews® & Seelbolts®

- Screw Material:

- 18/8 Stainless Steel, passivated

- Threads:

- Imperial— Class 2A †; Metric— Class 6g

- O-Ring Elastomer:

- Silicone conforms to A-A-59588, Class 2, GR60 or GR70, Red ‡

- Temperature Range:

- -80° F to +425° F ( -62° C to +219° C)

- Resistant to:

- Splash, salt spray, sunlight, ozone, weather, fungus, dust, and most acids and lubricating oils.

‡ Alternative o-ring elastomers are available. Consult our O-Ring Elastomer Options table for details.

| Thread Size | Drive Size | Min. Length Available (L) | Max. Head Diameter (C) | Recommended Clearance Hole (Min. - Max.) |

|---|---|---|---|---|

| 2-56 UNC-2A | #1 | 1/4" | 0.172" | 0.091" - 0.950" |

| 4-40 UNC-2A | #1 | 1/4" | 0.225" | 0.125" - 0.129" |

| 6-32 UNC-2A | #2 | 1/4" | 0.279" | 0.147" - 0.152" |

| 8-32 UNC-2A | #2 | 1/4" | 0.332" | 0.173" - 0.179" |

| 10-24 UNC-2A | #2 | 5/16" | 0.385" | 0.199" - 0.204" |

| 10-32 UNF-2A | #2 | 5/16" | 0.385" | 0.199" - 0.204" |

| 1/4-20 UNC-2A | #3 | 3/8" | 0.507" | 0.265" - 0.269" |

For a full list of part numbers, please contact APM Hexseal.

IMPERIAL HEXAGONAL HEAD BOLT

MATERIAL SPECIFICATIONS

For APM Hexseal® Standard Seelskrews® & Seelbolts®

- Bolt Material:

- 18/8 Stainless Steel, passivated

- Threads:

- Imperial— Class 2A †; Metric— Class 6g

- O-Ring Elastomer:

- Silicone conforms to A-A-59588, Class 2, GR60 or GR70, Red ‡

- Temperature Range:

- -80° F to +425° F ( -62° C to +219° C)

- Resistant to:

- Splash, salt spray, sunlight, ozone, weather, fungus, dust, and most acids and lubricating oils.

‡ Alternative o-ring elastomers are available. Consult our O-Ring Elastomer Options table for details.

| Thread Size | Min. Length Available (L) | Distance Between Flats (C) | Distance Between Points (P) † | Max. Head Height (D) | Recommended Clearance Hole (Min. - Max.) |

|---|---|---|---|---|---|

| 1/4-28 UNF-2A | 3/8" | 0.440" | 0.510" | 0.163" | 0.265" - 0.269" |

| 1/4-20 UNC-2A | 3/8" | 0.440" | 0.510" | 0.163" | 0.265" - 0.269" |

| 5/16-24 UNF-2A | 1/2" | 0.502" | 0.580" | 0.211" | 0.332" - 0.336" |

| 5/16-18 UNC-2A | 3/8" | 0.502" | 0.580" | 0.211" | 0.332" - 0.336" |

| 3/8-24 UNF-2A | 5/8" | 0.565" | 0.650" | 0.243" | 0.395" - 0.399" |

| 3/8-16 UNC-2A | 1/2" | 0.565" | 0.650" | 0.243" | 0.395" - 0.399" |

| 1/2-20 UNF-2A | 1/2" | 0.752" | 0.870" | 0.323" | 0.530" - 0.534" |

| 1/2-13 UNC-2A | 3/4" | 0.752" | 0.870" | 0.323" | 0.530" - 0.534" |

† The values provided for Distance Between Points are for reference only. |

|||||

For a full list of part numbers, please contact APM Hexseal.

METRIC HEXAGONAL HEAD BOLT

MATERIAL SPECIFICATIONS

For APM Hexseal® Standard Seelskrews® & Seelbolts®

- Bolt Material:

- 18/8 Stainless Steel, passivated

- Threads:

- Imperial— Class 2A †; Metric— Class 6g

- O-Ring Elastomer:

- Silicone conforms to A-A-59588, Class 2, GR60 or GR70, Red ‡

- Temperature Range:

- -80° F to +425° F ( -62° C to +219° C)

- Resistant to:

- Splash, salt spray, sunlight, ozone, weather, fungus, dust, and most acids and lubricating oils.

‡ Alternative o-ring elastomers are available. Consult our O-Ring Elastomer Options table for details.

| Thread Size | Min. Length Available (L) | Distance Between Flats (C) | Distance Between Points (P) † | Max. Head Height (D) | Recommended Clearance Hole (Min. - Max.) |

|---|---|---|---|---|---|

| M6 X 1 6g | 8mm | 10mm | 11.28mm | 4.15mm | 6.73mm - 6.83mm |

| M8 X 1.25 6g | 12mm | 13mm | 14.69mm | 5.65mm | 8.45mm - 8.55mm |

| M10 X 1.5 6g | 12mm | 17mm | 19.25mm | 7.18mm | 10.53mm - 10.64mm |

| M12 X 1.75 6g | 20mm | 19mm | 21.50mm | 8.18mm | 12.79mm - 12.9mm |

† The values provided for Distance Between Points are for reference only. |

|||||

For a full list of part numbers, please contact APM Hexseal.