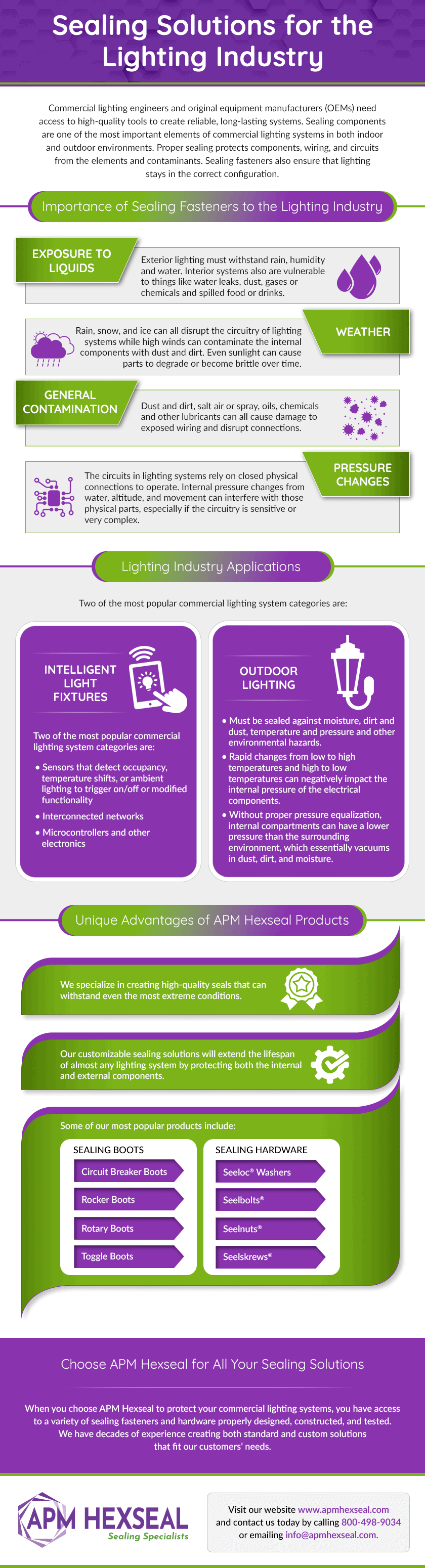

Commercial lighting engineers and original equipment manufacturers (OEMs) need access to high-quality tools to create reliable, long-lasting systems. Sealing components are one of the most important elements of commercial lighting systems in both indoor and outdoor environments. Proper sealing protects components, wiring, and circuits from the elements and contaminants. Sealing fasteners also ensure that lighting stays in the correct configuration.

Importance of Sealing Fasteners to the Lighting Industry

Lighting systems are becoming more energy-efficient and cost-efficient, technologically interconnected and sustainable. All of these qualities mean that lighting systems have more complex and sensitive components that need to be aligned and protected for the life of the system. Environmental factors that can damage a lighting system include:

- Exposure to liquids: Exterior lighting must withstand rain, humidity and water. Interior systems also are vulnerable to things like water leaks, dust, gases or chemicals and spilled food or drinks.

- Weather: Rain, snow, and ice can all disrupt the circuitry of lighting systems while high winds can contaminate the internal components with dust and dirt. Even sunlight can cause parts to degrade or become brittle over time.

- General contamination: Dust and dirt, salt air or spray, oils, chemicals and other lubricants can all cause damage to exposed wiring and disrupt connections.

- Pressure changes: The circuits in lighting systems rely on closed physical connections to operate. Internal pressure changes from water, altitude, and movement can interfere with those physical parts, especially if the circuitry is sensitive or very complex.

Lighting Industry Applications

Two of the most popular categories of commercial lighting systems are intelligent light fixtures and outdoor lights. Intelligent light fixtures often have the following components that need to be sealed against external contaminants:

- Sensors that detect occupancy, temperature shifts or ambient lighting to trigger on/off or modified functionality

- Interconnected networks

- Microcontrollers and other electronics

Outdoor lights, including architectural lights, floodlights and landscape lighting must also be sealed against moisture, dirt and dust, temperature and pressure and other environmental hazards, as one of the greatest threats to the longevity of outdoor lighting systems is temperature shifts. Rapid changes from low to high temperatures and high to low temperatures—such as in the morning or evening or during sudden onsets of bad weather—can negatively impact the internal pressure of the electrical components. Without proper pressure equalization, internal compartments can have a lower pressure than the surrounding environment, which essentially vacuums in dust, dirt, and moisture. Across time, lights can fail due to the accumulation of invasive contaminations.

High-quality sealing fasteners and boots protect lighting components from these hazards by sealing the gaps between buttons or switches and the main body of the lighting equipment. These sealing components can be custom designed and manufactured for the specific climate of the lighting’s environment.

Unique Advantages of APM Hexseal Products

At APM Hexseal, we specialize in creating high-quality seals that can withstand even the most extreme conditions. Our wide variety of standard and customizable sealing solutions will extend the lifespan of almost any lighting system by protecting both the internal and external components.

We provide sealing boots, bushing seals, and a full line of sealing hardware. Each component can be installed, removed and reused for easy access to internal components, repairs and maintenance, and system modifications.

Some of our most popular products include the following:

Sealing Boots

- Circuit breaker boots

- Rocker boots

- Rotary boots

- Toggle boots

Sealing Hardware

- Seeloc® Washers

- Seelbolts®

- Seelnuts®

- Seelskrews®

When you choose APM Hexseal to protect your commercial lighting systems, you have access to a variety of sealing fasteners and hardware properly designed, constructed, and tested. We have decades of experience creating both standard and custom solutions that fit our customers’ needs. Ask the experts today to see how we can develop the right custom sealing solution for any lighting system.