How to Choose the Right Sealing Boot for Your Next Project

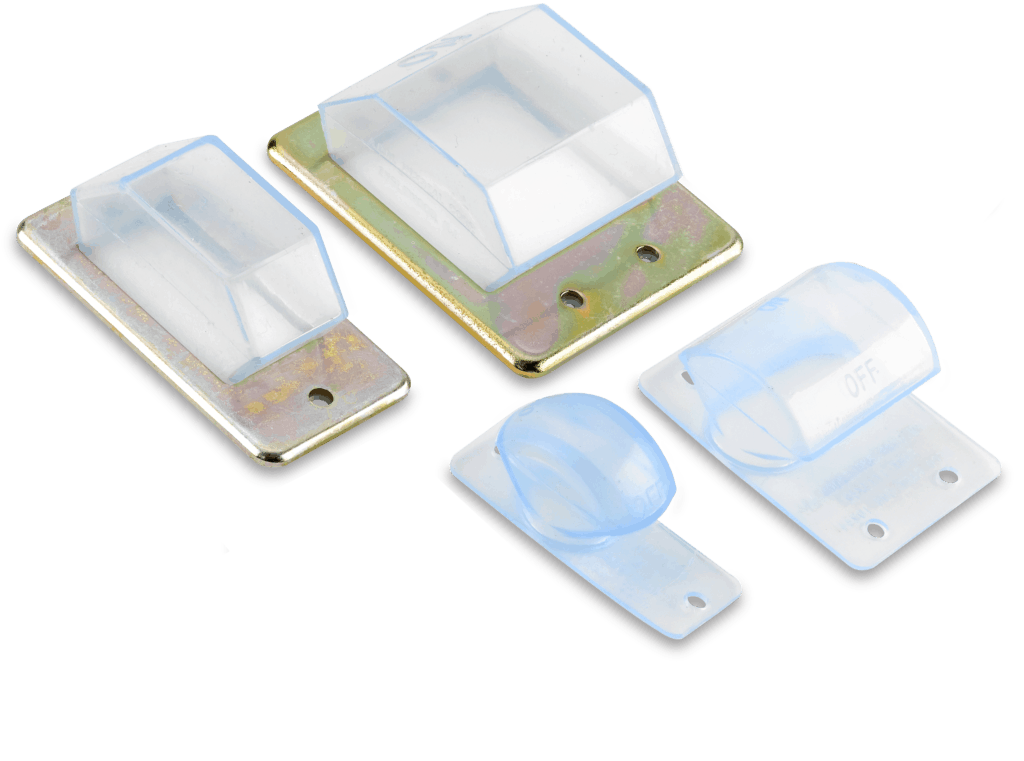

Mechanical and electrical controls such as control panels, circuit breakers, and switches can malfunction if not sealed properly and components are left vulnerable to harmful contaminants. Sealing boots function to guard those controls against various contaminants such as grease, cleaning solvents, sand, lubricants, liquids, saltwater, dust, and dirt. They are tough, flexible molded rubber devices used for rotary, rocker, pushbutton, and toggle switches. Choosing a proper sealing boot can help you prevent your electronic and mechanical controls from being damaged...